When setting up a soft wash system, you have lots of options when it comes to equipment. Selecting the right pump is one aspect that can make or break your entire setup. Softwash jobs require a balance of power to reach tall heights and low pressure to be gentle on surfaces.

The good news is that there are many options. The bad news is that all these options might have you feeling overwhelmed. Ultimately, any of these softwash pump options work. It comes down to your personal preferences and budget. So how about we get into the various softwash pump types and examine their pros and cons?

Pump Types Used for Softwash

A diaphragm pump is the most common pump type used in the softwash industry. The are different varieties in terms of the amount of flow and pressure they will achieve as well as the means used to power them.

12-volt and gas-engine-driven pumps are extremely common due to the mobile nature of the business. 110-volt, hydraulic, or air-driven can also be used if you have the means available, however, these often require more investment in additional equipment or access to electricity at the job site. In this guide, we are going to focus on the 12-volt and gas-engine pump options.

Another important factor is the material construction of the pump. Soft wash pumps need to be compatible with sodium hypochlorite solutions. The best materials for this application are polypropylene, Viton, Santoprene, and polyethylene.

12 & 24-Volt Soft Wash Pumps

Even if you are new to the softwash world, you will probably recognize this type of pump. 12-volt diaphragm pumps are extremely versatile and user-friendly. They are used in many different industries from RV's, marine, pest control, automotive, and more.

12-volt pumps come in a range of sizes. There are 12-volt pumps that can produce a maximum flow rate of about 7 GPM. The maximum PSI you can get from a 12-volt pump is about 700. However, you won't find one that delivers 7 GPM at 700 psi because 12 volts doesn't provide enough power to do so.

At higher pressure, these pumps are only capable of delivering a low flow rate, usually less than one gallon per minute. A 12-volt pump delivering 7 GPM will do so only at very low PSI. (We will get into the flow and pressure requirements needed for different jobs in the next section.)

24-volt diaphragm pumps operate the same as 12-volt diaphragm pumps but they generally offer higher flow rates and pressure, which means greater spray distance or reach.

Demand Pumps

The specific style of 12 & 24-volt pump used for softwash applications is a demand-style pump. A demand pump is designed to provide flow "on demand." This type of pump uses a pressure switch to automatically control the motor based on the pressure in the system.

When your spray wand trigger or valve is closed, the pressure builds up, and the demand switch shuts off the motor. When the trigger or valve is opened, the pressure drops, the switch deactivates, and the motor restarts, allowing liquid to flow again. This mechanism is used to help you conveniently operate your system without wasting battery or overheating your motor.

12/24-Volt Pump Pros & Cons

Pros

- Inexpensive

- Easy to replace

- Quiet

- No oil changes or re-fueling

Cons

- Shorter lifespan relative to other diaphragm pump types

- Repair costs often justify replacing the entire pump

- Cycling pressure switch can burn out the motor and relay

12-Volt Pump Options:

24-Volt Soft Wash Pumps:

You can see more 12 & 24-Volt options here.

Engine-Driven Diaphragm Pumps for Softwash

When it comes to mobile softwash options, 12V, and 24V pumps are handy but have limitations in flow and pressure. This is where gas engine-driven pumps step in. Thanks to the increased horsepower of a gas engine, these pumps can deliver a much higher volume per minute and significantly greater PSI.

The enhanced volume and pressure mean you can achieve spray distances and heights far beyond what a 12V pump can offer. With the right plumbing and spray gun/nozzle combination, you can easily reach distances over 50 feet. This capability makes tackling larger jobs such as commercial buildings a breeze. You can effortlessly spray buildings over two stories high and reach rooftops.

Moreover, gas engine-driven pumps are more durable. They can be rebuilt and will last several years if properly maintained. They are a long-term solution for extensive softwash needs.

Engine-Driven Diaphragm Pump Pros & Cons:

Pros

- Greater reach due to higher volume and pressure

- More volume for larger jobs and taller buildings

- Durable and repairable, equalling a longer lifespan

Cons

- Requires regular oil changes for both the pump and engine

- Diaphragms need periodic replacement

- More expensive to repair

- Additional cost of fuel to run the engine

- Significantly more expensive than 12-volt pumps

Engine-driven soft wash pump options

Sizing Your Softwash Pump

Probably the number one question you have is "What pump will help me spray two-story buildings, roofs, etc.". In other words, what is the spray distance of these different pumps?

It is crucial to understand that spray distance is not just a matter of your pump's size. The pump's flow and pressure specifications are the starting point. We can identify the potential reach from a particular pump, but the pump is not the only factor determining spray distance. The nozzle size, nozzle type, inside diameter of your hose, etc., will contribute to or detract from the effective spray distance of your softwash system.

There are two aspects of "pump size" to consider: the flow rate and the pressure it will produce. A pump needs to deliver enough flow that will allow you to cover an area quickly, but you don't want to overspend on a large pump if you don't need it. You also need the right combination of flow and pressure to propel your cleaning solution high enough to reach second-story walls and roofs.

With this in mind, we can pinpoint some common applications and the pumps that will work in those scenarios assuming you pair them with the proper equipment.

For more information on the accessories needed for effective softwash, you can view these pages on softwash spray guns and nozzles:

Recommended Pump Sizes for Common Soft Wash Applications

Residential Cleaning

Cleaning a two-story home requires a system to spray at least 20 feet in the air. And if you want to clean the roof as well, you're going to need more spray height than that. For these applications, you can rely on the 12-volt family of pumps that flow 5 GPM and reach pressures up to 100 PSI. Paired with the right nozzles and spray gun this pump will have no trouble reaching 30 feet or higher.

The Everflow SW5500 pump is specifically designed to be used with bleach and other types of disinfectant solutions. In addition to bleach-resistant materials, It features a motor shield that will shut off the pump if a leak is detected.

Of course, there are other 12-volt options available that work great: 12-Volt Softwash Pump Options

Commercial and Larger Projects

If you plan to do buildings that are taller than two stories and larger than a typical house, you may want to consider a gas engine-driven pump.

- Large Surfaces: For cleaning large commercial buildings, parking lots, or extensive residential properties, a pump producing more than 5 GPM is recommended. The increased flow rate can significantly reduce cleaning time.

- Multiple Users: If your setup involves multiple users cleaning different areas simultaneously, a higher flow rate pump will ensure that both operators receive sufficient solution pressure.

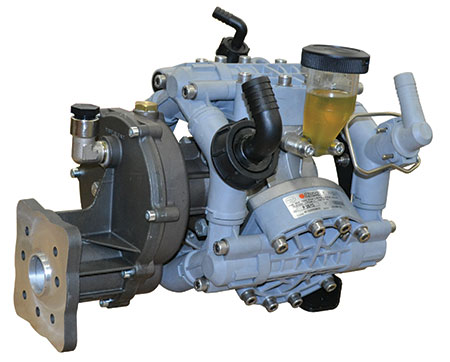

Example of Gas-Engine Driven Softwash Pump:

Conclusion

Selecting the right pump for your softwash system depends on your specific needs and the scale of your projects. 12-volt pumps are inexpensive and effective for residential jobs. If you plan to clean larger commercial buildings a gas-engine unit offers more flow and reliability but they are more expensive.

If you have questions or want to talk with someone about the softwash pump options available, give us a call

Tech Ag & Industrial Sales

Shane Blomendahl is a tech sales veteran at Dultmeier Sales with over 10+ years of experience in liquid handling products covering several industries and applications.