Banjo Corporation has a long history of creating innovative products. One of their biggest innovations came when they introduced manifold flange plumbing fittings into the agricultural spraying and industrial liquid handling industries. These flange fittings are designed to be used in place of threaded fittings. This advancement makes it much simpler and faster to assemble, disassemble and re-plumb systems without the hassle of dealing with threaded connections.

With manifold clamps, you can quickly remove and inspect sprayer components like flow meters and strainers without disassembling the entire system. This is a stark contrast to threaded systems where you must start at one end and disassemble parts until you reach the desired component.

Anyone who has ever replaced a cracked strainer or valve knows how difficult and time-consuming it can be to remove several hoses and fittings to replace your broken part, and then reassemble the entire thing. With manifold flanges, the component can be removed and replaced by just removing the flange clamps.

This guide will cover everything you might need to know when it comes to using manifold flanges, from the fittings themselves to how to correctly size a gasket for Banjo manifold flanges.

Understanding Manifold Flanges

A Banjo manifold flange is a type of connection used in sprayer systems to join various components such as pumps, valves, and hoses. These flanges are available in different sizes, and two flanges of the same size are connected with a manifold flange clamp. A gasket fits in between the two flanges to create a secure, leak-proof seal.

Banjo manifold flanges have been so widely adopted in the market that besides other different manifold fittings, these flanges have been integrated into the designs of pump housings, valves, strainers, flow meters, and more.

For example, Banjo, Hypro, and John Blue offer many pumps with manifold flange connections in place of pipe thread. There are also line strainers that have flanged ports in place of threaded ports. To help with the installation of manifold flanges, there are also U-bolts specifically designed for the various manifold fitting sizes.

Other manufacturers have made compatible flanges that will work with the Banjo manifold fittings, but the key is making sure that you match up the correct corresponding sizes.

Sizing Manifold Flanges

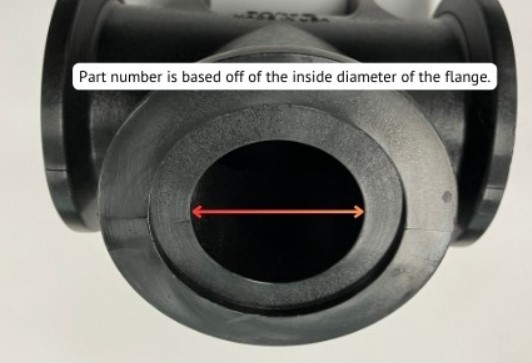

Banjo manifold flange fittings come in four standard sizes: 1-inch, 1.5-inch (also referred to as a 2-inch standard port), 2-inch full port, and 3-inch. Understanding their inside diameter is crucial for determining flow capacity and ensuring effective use of these fittings. Despite the varying naming conventions across different manufacturers like Banjo, Hypro, and TeeJet, compatibility is straightforward if the correct sizes are identified.

A common source of confusion is that Banjo labels their 1.5-inch inside diameter flange as a 2-inch "standard port" flange, while their 2-inch inside diameter flange is called a 2-inch "full port" flange. Banjo uses M200 and M220 as the part numbers for their 2-inch standard port and 2-inch full port flanges. Hypro refers to their 1.5-inch diameter flange fittings as 150-series flanges. This means a Hypro 150 series clamp will fit a Banjo M200 series flange. The same is true for the gaskets.

These part numbering systems are confusing. The chart below shows the different flange sizes and what part number from each manufacturer will work with each size.

Compatible Part Numbers for Each Manifold Flange Size

|

Manifold Flange Size |

Inside Diameter Measurement |

Banjo Part Number |

Hypro Part Number |

TeeJet Part Number |

|

1-inch |

1-inch |

M100 |

100 |

50 |

|

1.5-inches (2-inch standard port) |

1.5-inches |

M200 |

150 |

75 |

|

2-inch full port |

2-inches |

M220 |

200 |

na |

|

3-inch |

3-inches |

M300 |

300 |

na |

Compatible Manifold Flange Gasket Part Numbers

|

Manifold Flange Size |

Banjo |

Banjo Viton |

Banjo Skirted Gaskets |

Hypro EPDM |

Hypro Viton |

|

1-inch |

TKM100G |

TKM100GV |

TKM102G |

HYUFG0100E |

HYUFG0100V |

|

1.5-inches (2-inch standard port) |

TKM201G |

TKM150GV |

TKM202G |

HYUFG0150E |

HYUFG0150V |

|

2-inch full port |

TKM221G |

TKM200GV |

TKM222G |

HYUFG0200E |

HYUFG0200V |

|

3-inch |

TKM301G |

TKM300GV |

TKM302G |

HYUFG0300E |

HYUFG0300V |

Skirted Gaskets

Both Hypro and Banjo offer "skirted" gaskets. These gaskets are designed to stay in place when installed in a manifold. This allows you to install flange clamps without worrying if the gasket is seated correctly.

Compatible Clamps for Each Manifold Flange Size

|

Clamp Part Numbers |

Standard Clamp |

T-Bolt Clamps |

Bolted Heavy Duty Clamps |

Hypro Clamp |

|

1-inch |

FC100 |

na |

na |

HYC100 |

|

1.5-inches (2-inch standard port) |

FC200 |

na |

na |

HYC150 |

|

2-inch full port |

FC220 |

TKFC220TB |

TKFC220B |

HYC200 |

|

3-inch |

FC300 |

TKTC300TB |

TKFC300B |

HYC300 |

Banjo offers three different types of clamps for their manifold flanges. The first type is a standard worm gear clamp. This is the most economical and works well when there isn't too much weight or movement from the adjacent components.

T-bolt flange clamps are another clamp option, and these clamps are ideal for use with larger, heavier hoses or pipes. Finally, the heavy-duty bolted clamp is best suited for applications where significant weight may be applied to the clamp.

For example, if you have a 3-inch hose connected to a manifold flange outlet on a pump and you move the hose around, it can put strain on the flange clamp. The heavy-duty bolted clamp is the best option in this case as it is designed to withstand this frequent stress, ensuring the integrity of your connections.

Hypro manifold flange clamps are made of poly, and they are also T-bolt-style clamps. The big advantage of the Hypro clamp, however, is the hinged design. This makes it even easier to get the clamp around the flange after your fittings are in place.

You can view all the different flange clamps and gaskets on this page.

Different Types of Flange Fittings

The manifold flange fittings are primarily available in polypropylene, but some stainless-steel fittings are also available. There is a poly manifold fitting to replace just about any standard pipe thread plumbing fitting you can think of, though some of the most common are:

- Elbows

- Couplings

- Lugs/Caps

- Hose Barbs

- Reducers

- Crosses

- Tees

You can see the full selection of poly manifold fittings here.

Final Word

Flange fittings have been incorporated into about every type of sprayer component used today, from pumps and valves to flow meters and strainers.

Banjo Corporation's manifold flange fittings simplify assembly, disassembly, and re-plumbing in ag spraying and industrial systems. These fittings are compatible with many other manufacturers components, and so long as you are comfortable identifying the correct corresponding size needed, you're unlikely to encounter many issues using these flange fittings. If you have any questions about manifold flange fittings, please contact us.

Tech Ag & Industrial Sales

Shane Blomendahl is a tech sales veteran at Dultmeier Sales with over 10+ years of experience in liquid handling products covering several industries and applications.