If you spray deicing fluids on roads or sidewalks, you need your equipment to work whenever winter weather is going to arrive. Your pump is one of the most crucial components of a deicing and snow removal operation. Taking the time to find a reliable option will save you time and money in the long run.

Dultmeier Sales has been providing pumps and equipment for all types of anti-ice and deicing fluids. Today we will examine the optimal pump units for various de-ice scenarios.

Types of Pumps for Use With Deicing Liquids

Many different types of pumps can work with deicing liquids, but centrifugal pumps are the best option for the high-volume transfer requirements of large-scale ice prevention on roads and parking lots.

The specific centrifugal pumps used should be able to handle the corrosiveness and heaviness of deicing fluids. A few common deicing liquids include salt brine (NaCl), magnesium chloride (MgCl), and Calcium Chloride (CaCl). There are others such as Potassium Acetate and products that include natural byproducts such as sugar beet and corn-based additives.

Most of these deicing liquid products are quite corrosive, so pumps constructed of polyethylene, polypropylene, and stainless steel are much better choices than those constructed of cast iron, ductile iron, or aluminum. You can learn more about the materials compatible with salt brine and other device liquids in this de-ice equipment guide that covers the types of tanks, hoses, strainers, etc. that you need.

Standard single mechanical seals with Viton or EPDM elastomers are typically suitable for most deicing liquids, although double mechanical seals are even better with all products and are best for the deicing liquids that have solids in them such as the sugar beet or corn-based additives.

Transfer Pump Units with Electric Motors

For deicing liquids, centrifugal transfer pumps should be constructed of polyethylene, polypropylene, or stainless steel and should include electric motors that are Totally Enclosed and Fan-Cooled (TEFC). These are generally in the 2” or 3” size and most are self-priming.

Here you can see the polyethylene pump units with TEFC electric motors that we stock: Dultmeier Sales 2 - 10 HP Polyester Centrifugal Pump / Motor Units, Self-Priming - Dultmeier Sales

For deicing Liquids, it is important to select models with a Specific Gravity (S.G.) Rating of at least 1.2 or higher; this means the pump unit can safely pump liquids that are heavier than water (which has a 1.0 S.G. Rating). This will typically be 3HP, 5HP for 2” sizes, and 7.5HP or 10HP for 3” sizes. This will prevent the electric motor from overloading and tripping circuit breakers when pumping at high flow rates.

Recommended High-Volume Deice Liquid Transfer Pumps:

- Poly pumps won't rust and will hold up to corrosive liquids: Electric Motor-Driven Poly Transfer Pump Units

- Stainless steel is more costly, but in addition to being corrosion resistant, they are much more durable in the cold: Stainless Steel Electric Motor Driven Transfer Pump Units

Transfer Pump Units with Gas Engine Drives

These centrifugal transfer pumps are popular where sufficient electrical power is not available. Be sure to select 5HP engine models in the 2” sizes and at least 6.5HP for 3” size pumps. Here are some popular 2” Polypropylene Transfer Pumps with 5HP Honda Gas Engines that we stock:

Sprayer Pumps with Hydraulic Motors

Centrifugal Transfer Pumps are designed to move relatively high volumes of liquid (100 to 300 GPM for 2” and 3” sizes) but not for high-pressure spraying. So for Anti-ice and De-ice Sprayers, it is important to use centrifugal pumps that are designed for spraying. These pumps can generate much higher pressures than centrifugal transfer pumps. Most of these centrifugal sprayer pumps have integral hydraulic motors and run off the hydraulic hoses that run into and out of the hydraulic motor on the pump.

Many models can develop pressures of 80 to 100 PSI, so they can force liquid through the spray nozzles at sufficient volume to properly anti-ice and de-ice the roadways. It is very important to size your sprayer pump properly for the application rate (in gallons per lane-mile) and average speed your truck will be driving. We can assist you with sizing these sprayer pumps.

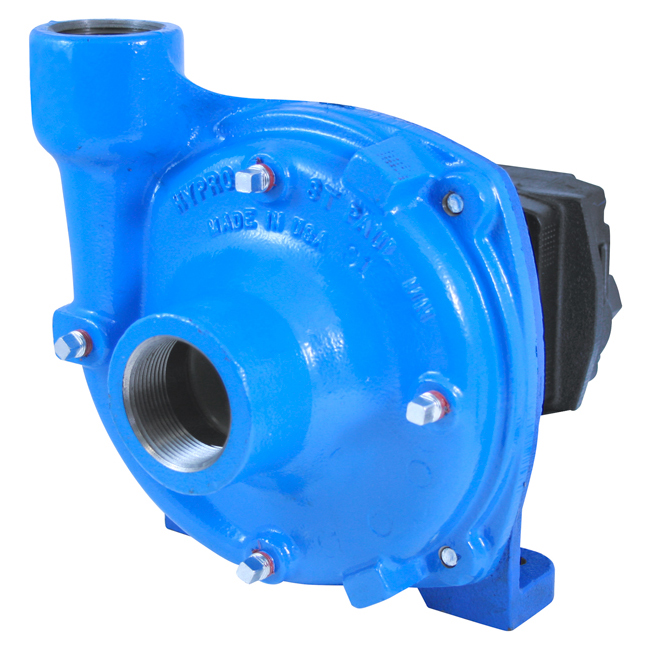

It is also important to select a sprayer pump with the correct hydraulic motor to match your hydraulic system's oil flow rate (gallons per minute of hydraulic oil). Note that these pumps can be constructed of cast iron and will last reasonably long with deicing liquids if flushed out periodically (and definitely after each spray season and then filled with RV Anti-Freeze or other non-corrosive liquids).

Here are some centrifugal sprayer pumps (cast iron and stainless shown) with hydraulic motors from Hypro that are popular for spraying deicing liquids at proper application rates and speeds:

Maintenance: Always remember to flush out all deicing liquids from your pump units right after the season ends and fill them with RV Anti-Freeze or other non-corrosive liquid. This will help your pumps last many years.

Tech Sales and Engineers on Staff to Assist You: We can help you size and select the correct transfer pumps and sprayer pumps for your liquid deicing applications. Just give us a call.

Tom Hansen, P.E.

Tom Hansen, Partner and Engineer at Dultmeier Sales, brings over 25 years of expertise in fluid handling equipment for agriculture, deicing, petroleum, and more.