Call for Live Order Assistance & Technical Support (7:30am-5pm CST)

You have no items in your shopping cart.

Polypropylene Fittings

from Banjo, Delavan, Flojet and Shurflo

Polypropylene, more commonly called "poly" or "polypro," has a wide range of chemical compatibility (resistance). It can handle many phosphoric acids, up to 40%, aggressive ag chemicals, soaps, waxes, and much more. This expansive chemical coverage is why polypropylene is so widespread. Products that should be avoided when using polypropylene include Nitric Acid, Bleach, and Chlorine. In addition, Creosote should be avoided due to the relatively low-temperature range of polypropylene. Oil based products such as hydraulic oil, kerosene, and diesel fuel are not recommended for polypropylene either. While most of these products can be transferred through polypropylene, over time the solution would erode the fittings and render the plumbing system useless. Polypropylene fittings are extremely diverse and can be used in a wide variety of applications. Most poly fittings are low pressure, meaning they have a working pressure of 150 PSI or lower. These fittings are injection molded using a die-cast to form the various sizes and shapes required. This plastic can be dyed virtually any color. Polypropylene is the second most produced plastic, only trailing polyethylene. Polyethylene is fairly similar to polypropylene; the most notable differences are different chemical compatibilities and temperature ranges.Crosses, Polypropylene

Banjo Valves & Fittings

GROUP_10533

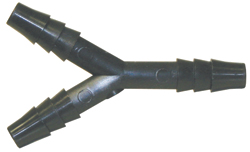

Crosses, Polypropylene

Quantity Discounts Available

From $14.40

Female Connector (Tube x FPT)

John Guest Fittings

GROUP_10474

Female Connector (Tube x FPT)

Quantity Discounts Available

From $3.30

Female Connector, Polypropylene (Tube x FPT)

GROUP_11057

Female Connector, Polypropylene (Tube x FPT)

Quantity Discounts Available

From $2.50

Female Elbow, Polypropylene (Tube x FPT)

GROUP_10961

Female Elbow, Polypropylene (Tube x FPT)

Quantity Discounts Available

From $3.10

Fixed Elbow (MPT x Tube)

John Guest Fittings

GROUP_10487

Fixed Elbow (MPT x Tube)

Quantity Discounts Available

From $2.20

Fixed Elbow (MPT x Tube)

John Guest Fittings

GROUP_11489

Fixed Elbow (MPT x Tube)

Quantity Discounts Available

From $2.50

Fixed Elbow (MPT x Tube)

John Guest Fittings

GROUP_11490

Fixed Elbow (MPT x Tube)

Quantity Discounts Available

From $2.70

Flange Plug with Gauge Port

Banjo Valves & Fittings

GROUP_10453

Flange Plug with Gauge Port

Quantity Discounts Available

From $10.40

Flange x Female Pipe Thread (FPT)

Banjo Valves & Fittings

GROUP_10446

Flange x Female Pipe Thread (FPT)

Quantity Discounts Available

From $2.70

Flange x Flange Coupling

Banjo Valves & Fittings

GROUP_10449

Flange x Flange Coupling

Quantity Discounts Available

From $5.80

Flange x Hose Barb

Banjo Valves & Fittings

GROUP_10455

Flange x Hose Barb

Quantity Discounts Available

From $2.40

Flange x Hose Barb Tee

Banjo Valves & Fittings

GROUP_11305

Flange x Hose Barb Tee

Quantity Discounts Available

From $8.40

Flange x Male Adapter (CAM)

Banjo Valves & Fittings

GROUP_10447

Flange x Male Adapter (CAM)

Quantity Discounts Available

From $6.40

Flange x Male Thread Adapter (MPT)

Banjo Valves & Fittings

GROUP_10444

Flange x Male Thread Adapter (MPT)

Quantity Discounts Available

From $2.80

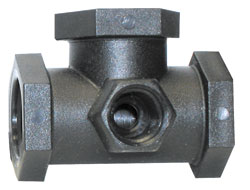

Flanged Cross, Polypropylene

Banjo Valves & Fittings

GROUP_10443

Flanged Cross, Polypropylene

Quantity Discounts Available

From $19.60

Gauge Tee, Polypropylene

GROUP_11523

Gauge Tee, Polypropylene

Quantity Discounts Available

From $20.90

Hose Menders, 304 & 316 Stainless Steel, 1" through 6"

GROUP_10999

Hose Menders, 304 & 316 Stainless Steel, 1" through 6"

Quantity Discounts Available

From $5.90

Hose Menders, 304 & 316 Stainless Steel, 1/4" through 3/4"

GROUP_11414

Hose Menders, 304 & 316 Stainless Steel, 1/4" through 3/4"

Quantity Discounts Available

From $3.05

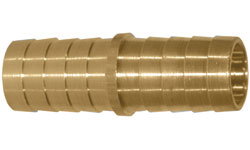

Hose Menders, Brass, 1/4" through 3/4"

GROUP_10997

Hose Menders, Brass, 1/4" through 3/4"

From $1.20