In the world of cleaning, high-pressure nozzles play a crucial role in delivering the power and precision needed to tackle tough jobs. Whether pressure washing a driveway, detailing a car, or performing industrial cleaning, the right high-pressure nozzle can make all the difference.

These nozzles are designed to enhance the effectiveness of your cleaning equipment by focusing water pressure into a powerful stream, capable of removing dirt, grime, and stains that would be impossible to eliminate with ordinary nozzles. They are typically constructed from stainless or hardened stainless steel to withstand high pressures.

Here's a comprehensive look at what you need to know about high-pressure nozzles.

High-Pressure Nozzles Applications

Most nozzles are rated to working pressures up to 4,000 psi, but higher-rated nozzles (up to 10,000 psi) are also available for more intense cleaning needs. Different pressure ranges are required to tackle the various cleaning tasks. It is important to identify the proper operating pressure for your scenario and size the nozzle accordingly.

Here are some common applications and the general pressures required:

Pressure Washing

From driveways and sidewalks to commercial buildings and heavy equipment, pressure washing relies on high-pressure nozzles to deliver targeted cleaning power. These nozzles help remove stubborn dirt, mildew, and other contaminants.

- Pressure Range: 1000 - 4000 PSI, Nozzle Options: SS Quick Coupler Nozzles & Stainless NPT Nozzles

Car Wash

In the automotive industry, high-pressure nozzles are essential for achieving a spotless finish. They are used in both automatic car washes and self-serve bays to apply foam, rinse off detergents, and remove dirt without damaging the vehicle's surface.

- Pressure Range: 1200 PSI - 2200 PSI, Nozzle Options: SS Quick Coupler Nozzles & Stainless NPT Nozzles

Industrial Cleaning

Factories, warehouses, and other industrial settings require heavy-duty cleaning solutions. High-pressure nozzles are often used in automated cleaning. They can be fixed to a machine or apparatus that is part of an industrial process to clean, strip, or prepare surfaces. Ideal for cleaning machinery, floors, walls, and other surfaces that accumulate grease, oil, grime, and other residues.

- Machinery Cleaning: Typically, 2,000 to 5,000 PSI to remove grease and grime.

- Paint Stripping: Around 5,000 to 10,000 PSI to effectively remove paint from surfaces.

- Surface Preparation: Up to 10,000 PSI (or even more in some cases!) for tasks like removing coatings, rust, or other surface contaminants before applying new coatings or treatments.

- Nozzle Options: Rotating Nozzles & Stainless NPT Nozzles

Selecting the Proper High-Pressure Nozzle

The benefits of using the right high-pressure nozzle for specific tasks cannot be overstated. Selecting the appropriate nozzle ensures:

- Efficiency: The correct nozzle maximizes cleaning power and reduces the time needed to complete a task.

- Safety: Using the right nozzle minimizes the risk of damage to surfaces.

- Cost-Effectiveness: Proper nozzle selection can extend the life of your cleaning equipment and reduce the need for additional cleaning agents.

To identify the right nozzle for your needs there are several things to consider in addition to the pressure rating of the nozzle. These include the spray angle, pattern, material, flow rate, and other nozzle features such as stabilizing vanes and rotating turbines.

Understanding Spray Angles and Patterns of High-Pressure Nozzles

The spray angle of a nozzle determines the coverage pattern and effectiveness at various distances from the surface. Common spray angles include:

- Zero Degree: Provides a concentrated, powerful spray for tough cleaning tasks. All fluid is directed in a narrow stream that impacts the surface in a very small area. Excellent for cutting through surfaces.

- 15 Degree: Offers a narrow, but slightly wider spray pattern; common for pressure washing and industrial cleaning.

- 25 Degree: Delivers a wider spray pattern, ideal for car wash and truck wash operations.

- 40 Degree: Provides the widest common spray pattern, excellent for general cleaning tasks.

A nozzle with a narrower spray angle will deliver more impact than a wider fan. So it is important to identify a good balance between the impact you need and the fan angle desired. Often the best way to determine this is by testing some different angles in your application, but knowing this can provide a good starting point.

Sizing a High-Pressure Nozzle

In addition to the spray angle, you need to determine the nozzle size for your application. The orifice size of a nozzle affects the flow rate (measured in gallons per minute, GPM) through the nozzle.

Nozzles are sized based on their flow capacity at 4000 PSI. In other words, how many gallons will flow through the tip/orifice of the nozzle at 4000 PSI? For example, a #4 nozzle will flow 4 GPM at 4,000 PSI. A #3 nozzle will flow 3 GPM at 4000 PSI.

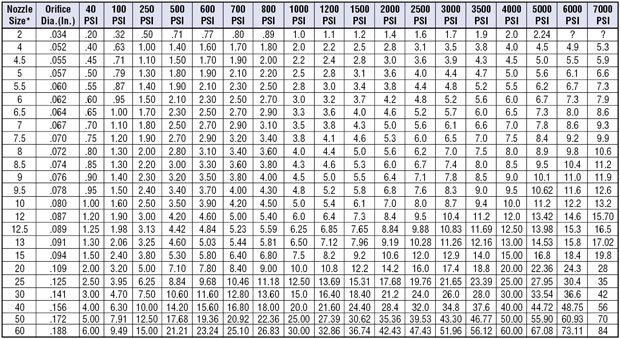

This chart shows the flow capacity of each orifice size at various pressures:

Identifying your nozzle size requires that you know the parameters of your system and size a nozzle accordingly. Let's look at an example: a pressure washer that delivers 3 GPM at 2000 PSI. Using the chart, you can find 2000 PSI at the top and follow the column down until we get to 3 GPM. Then we can follow the row left to the nozzle size column on the far left of the chart. This shows us that a 4.5 nozzle or orifice size will flow 3 GPM at 2000 PSI.

This nozzle will work for the system in our example, but it is a good rule of thumb to select a nozzle size slightly smaller than what you find in this chart. In this case a #4. This will provide some bypass and allow for nozzle wear over time without a decrease in pressure.

If you are unsure of any aspect of nozzle sizing, you can always get in touch with our high-pressure cleaning team!

Nozzle Features

While spray pattern and nozzle size are the two main factors you must consider, there are other nozzle features and attributes to keep in mind.

- Internal Stabilizer Vanes: Some nozzles come with internal stabilizer vanes which create a more defined spray pattern. These are particularly useful in industrial or process cleaning where precision is a necessity.

- Rotating Nozzles: High-pressure rotating nozzles or Turbo Nozzles have an internal turbine that creates a rotating stream that vastly improves efficiency when compared to flat fan nozzles.

- Pipe Thread Sizes: High-pressure nozzles are usually available in 1/8" or 1/4" male or female pipe thread sizes, making them compatible with existing wands, arches, or other cleaning equipment.

- Quick Coupler Nozzles: Designed to fit 1/4" quick coupler fittings, allowing for easy change out or removal.

By choosing the right nozzle, you can maximize cleaning efficiency and ensure that your equipment operates at peak performance.

Conclusion

High-pressure nozzles are a key component in effective cleaning systems. Understanding their types, features, spray angles, and orifice sizes can greatly enhance your cleaning results. Always ensure you're using the right nozzle for your specific application to achieve the best performance and longevity from your equipment.