Despite all the expensive and sophisticated components on a sprayer, the tiny nozzles on your boom are still the number one factor impacting your sprayer's performance. You may have a high-volume pump, state of the art GPS guidance system, and stainless-steel boom, but the nozzle ultimately has the greatest influence on a sprayer's effectiveness.

One of the main factors a sprayer nozzle dictates is the droplet size that is dispersed over the target. Droplet size is important because it affects several aspects:

- Drift: Larger droplets are less prone to drifting to areas you don't want sprayed, such as your neighbor's field

- Coverage: Smaller droplets can typically provide better coverage, giving you the best chance to eliminate targeted weeds or pests

- Penetration: Droplet size affects ability to penetrate dense canopies, ensuring that pests or weeds are effectively targeted

- Adherence: Smaller droplets tend to adhere better to plant surfaces

- Evaporation: Affects amount of liquid deposited on the target area rather than being lost to the surrounding environment or evaporation

When selecting a nozzle for your sprayer, it is vital to not only consider the droplet size but also the entire droplet size range a nozzle produces. In the rest of this guide, we will look at what droplet size means, what affects droplet size, and how different nozzles compare.

Understanding Droplet Size

Droplet size refers to how big each droplet of sprayed liquid is. Their size is measured in microns. A micron (1 µ) is a very tiny unit equal to 1/25,000 of an inch or about 0.001 millimeters. So, when we talk about droplet size, we're talking about the diameter, or width, of each droplet.

Just like sprayer nozzle sizes, droplet size classification is defined by international standards (ISO 25358 and ASABE S572.3). This classification system divides droplet sizes into specific categories so different nozzle types and brands can be compared. The categories are as follows:

|

Droplet Size |

Abbreviation |

Color Code |

Approx Micron Range |

|

Extremely Fine |

XF |

Purple |

Less than 60 |

|

Very Fine |

VF |

Red |

60 to 145 |

|

Fine |

F |

Orange |

146 to 225 |

|

Medium |

M |

Yellow |

226 to 325 |

|

Coarse |

C |

Blue |

326 to 400 |

|

Very Coarse |

VC |

Green |

401 to 500 |

|

Extremely Coarse |

XC |

White |

501 to 650 |

|

Ultra Coarse |

UC |

Black |

Greater than 650 |

These categories help in identifying and selecting the appropriate droplet size for different agricultural spraying applications. Each category is defined by specific droplet size ranges measured in microns (µ).

Spray nozzle charts show the droplet size produced by a nozzle at various pressures. It will be displayed with the abbreviation and color code shown above. It is important to note that this indicates the size of the majority of the droplets and not all the droplets dispersed by that particular nozzle.

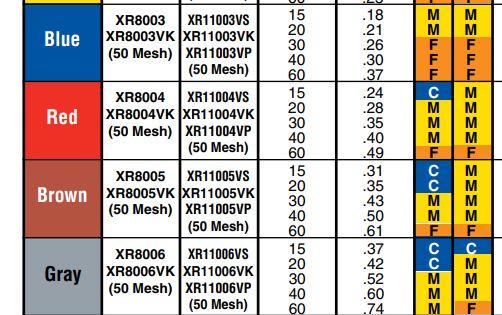

Example: If a nozzle chart indicates that a sprayer tip will produce Coarse (C) droplets, that nozzle can still produce finer droplets, but the majority will be Coarse. The image below shows the droplet size produced by the different sizes of a nozzle at various pressures:

You can see in the chart that a red nozzle (04 size) will most often produce Medium (M) droplets within the pressure range of 20-40 PSI. If the operating pressure is below 20 PSI, however, then the size of droplets produced changes from Medium to Coarse (C). Conversely, if the pressure increases to 60 PSI the majority of the droplets will be Fine (F).

How Droplet Size Impacts Spray Quality

Drift: When it comes to spraying, drift is a major concern. Not only does drift reduce the effectiveness of your spray, but it can pose a potential threat to neighboring crops, waterways, wildlife, and people. Larger droplets are less prone to drift because they are heavier and fall more directly onto the target. This means they are less likely to be carried away by the wind. ensuring that your herbicide lands where it's intended and not on neighboring crops or non-spray areas.

Another important concept to understand when discussing drift and considering nozzle selection is driftable fines. These are the very small droplets that are extremely susceptible to drift. Any droplet under 150 microns (µ) is considered a draftable fine. Nozzle literature typically indicates the percentage of the droplets produced by that specific nozzle that fall into the category of driftable fines.

Here are two videos illustrating the importance of selecting the proper sprayer nozzle and the effect that droplet size has on drift reduction:

You can see there is a clear difference between the amount of liquid affected by wind, highlighting the importance of nozzle selection.

Coverage: Smaller droplets generally provide better coverage. They can spread more evenly over the target surface, which is essential for effective pest and weed control. However, this also means they are more susceptible to drift, so it's a balancing act to achieve the right droplet size for your specific needs.

As the videos above show, even though smaller droplets provide better coverage in ideal conditions, you can potentially get better coverage from larger droplets because more liquid is getting to the target.

Penetration: Droplet size significantly affects the ability to penetrate dense canopies. Smaller droplets can move more easily through thick foliage, ensuring that the herbicide reaches the inner parts of the plant where pests or weeds might be hiding. This thorough coverage is vital for effective treatment.

Adherence: Smaller droplets tend to adhere better to plant surfaces. Their lightweight nature allows them to stick more easily to leaves and stems, providing a more uniform application and treatment. This is particularly important for contact herbicides, which need to stay on the plant surface for a period of time to be effective.

Deposition/Evaporation: The size of the droplets also influences the amount of liquid deposited on the target area versus what is lost to the surrounding environment or through evaporation. Larger droplets deposit more liquid on the target, reducing the amount lost to evaporation. This means more of the herbicide remains on the plants, enhancing its effectiveness and reducing waste.

How a Sprayer Nozzle Impacts Droplet Size

The importance of choosing the proper spray nozzle cannot be understated, because it is the very design of a nozzle that has the greatest impact on droplet size. As the liquid comes out of the sprayer nozzle, it doesn't just flow smoothly; instead, it breaks up from a solid "sheet" to smaller sheets (also called ligaments), and then finally droplets. The size and spread (spray pattern) of the droplets depends heavily in how the spray tip was engineered but can also change depending on the viscosity of the liquid, the flow rate of the nozzle, and the pressure at which the nozzle/liquid is being sprayed/p>

The size and distribution of the nozzles throughout the width of the spray pattern varies depending on the nozzle type. Nozzles have precise, intricate internal fluid paths designed to generate a specific range of droplet sizes.Some herbicides require that you use a nozzle with larger droplets. Typically, in the extremely coarse range or larger. One of the common means used by nozzle manufacturers to create larger droplets is air induction.

This is the process of pulling air into the nozzle to fill the droplets with air, resulting in an overall larger sized droplet. There are several different nozzle types that accomplish this, and different manufacturers utilize different designs.

It's important to note that not all nozzles that produce extremely coarse or ultra coarse droplets use air-induction technology. As more sophisticated spray methods are developed, nozzle technology will continue to adapt to increase efficiency and precision.

Selecting the Right Droplet Size for Your Application

The details behind droplet size creation and classification are important but ultimately the most important question is, "What droplet size do I need for my application and which nozzle will produce it for me?"

Answering that question requires that we consider all the factors involved in your specific scenarioThe first and most important guideline is the pesticide label. If specific instructions are provided in the product label in terms of droplet size required, then that guideline is the lawFollowing the label ensures you have the best chance at avoiding any unintended consequences during or after spraying. In addition to this, there are several other aspects of spraying that might indicate you should use a droplet size that is finer or coarser.

Here are several factors to consider and why they would potentially affect which size droplets you need:

- Crop Type: The foliage and leaves of various crops can present obstacles. For example, if you need to penetrate a dense canopy you may want nozzles that produce smaller droplets for better penetration.

- Pesticide Type: The type of pesticide-whether it's a herbicide, insecticide, or fungicide-affects nozzle choice. Contact pesticides generally need smaller droplets for thorough coverage, whereas systemic pesticides can use larger droplets.

- Target Pest or Disease: The specific pest or disease being targeted dictates the required droplet size. For instance, pests on the underside of leaves or deep within the canopy might require smaller droplets that can navigate through the foliage, whereas surface pests can be controlled with larger droplets.

- Weather Conditions: Wind, temperature, and humidity significantly impact spray applications. Windy conditions necessitate nozzles that produce larger droplets to reduce drift, while calm conditions allow for finer droplets. High temperatures and low humidity increase evaporation rates, so larger droplets may be needed to ensure adequate deposition.

- Drift Tolerance: Areas with sensitive neighboring crops or habitats require nozzles that minimize drift. Air induction nozzles producing very coarse droplets are often used in such scenarios to keep the spray on target and prevent damage to surrounding areas.

- Spraying Speed: The speed at which you spray affects droplet size and distribution. Faster speeds can cause smaller droplets to drift, so selecting nozzles that produce larger droplets at higher speeds can help maintain effective coverage and reduce drift. When spraying across a range of speeds, you need a nozzle that will maintain your desired droplet size range at both lower and higher pressures.

- Operating Pressure: The pressure at which the spray system operates impacts droplet size. Higher pressure generally produces finer droplets, while lower pressure produces coarser droplets. Choosing nozzles compatible with your operating pressure ensures consistent and effective spray patterns.

- Boom Height: The height of the spray boom above the crop affects coverage and drift. Lower boom heights reduce drift but require nozzles that can maintain a uniform spray pattern at closer range. Higher boom heights need nozzles that produce larger droplets to ensure they reach the target without drifting.

Note: These are guidelines, no two applications are going to be the same and there may be more factors you need to consider.End users should always speak with their local crop consultant for specific application requirements/nozzle selection.

With so many different things to keep in mind, landing on one specific spray nozzle can be quite the task. The good news is that there are likely several nozzle types across the different manufacturers that will work in your scenario. The key is trying to zero in on one that will provide the best results based on all the variables involved.

Nozzle selection may involve some trial and error, but we can get you off to a good start. The nozzle manufacturers offer extensive resources that detail the droplets sizes and other performance factors of a given type of nozzle family.

They also provide nozzle selection tools to walk you through the process:

- TeeJet Spray Select Tool

- Greenleaf Nozzle Recommendation Tool

- Wilger Tip Wizard

- Hypro Nozzle Decision Tool

Selecting a sprayer nozzle also involves calculating the correct nozzle size for your application rate. For more information on this, be sure to examine this guide to sizing sprayer nozzles as well as the complete guide to sprayer nozzle numbers.

Recommended Sprayer Nozzles for Various Droplet Size Requirements

Dultmeier sales carries a wide selection of sprayer nozzles that deliver a wide range of droplet sizes. Whether you need fine droplets for thorough coverage of plant tissue, need larger droplets to follow herbicide label requirements, or you require a nozzle that is approved for use with a PWM system:

- Broadcast Sprayer Nozzles - Nozzles for reduced drift, insecticides, fertilizer, contact herbicides, soil applied, etc.

- Approved Nozzles for 2, 4-D Based Product & DiCamba Product

- PWM Approved Sprayer Nozzles

Sizing Nozzles for a PWM system is a bit different than for standard spray nozzles. Learn more in this article on properly sizing nozzles for PWM.

Maximize Coverage with Coarser Droplets

One of the natural concerns when using a nozzle that produces larger droplets is "Will I still get good coverage?". With all things being equal, traditional flat fan nozzles like the Turbo Teejet or XR Teejet, which produce droplets in the Coarse, Medium, and Fine categories, offer better coverage. However, when we add in higher spraying speeds (10+ MPH), consistent wind (no one ever deals with wind while spraying, right?), and significant evaporation conditions, larger droplets can deliver more spray on target because they are more resistant to these factors.

When Extremely Coarse and Ultra Coarse droplet sizes are required but you are still concerned about adequate coverage, there are some options. For one, you can utilize dual fan nozzles instead of single flat fan nozzles.

Dual fan nozzles still produce the same size droplet as a single fan nozzle, but there are two separate spray fans directed at the target, at two different angles. Two fans allow you to retain desired droplet size while also increasing the number of spray angles at which to spray your target. More spray angles equals better coverage.

TTI TwinJet Nozzles Provides 2 fans at a 60-degree angle from one another.

GreenLeaf Dual Fan Nozzles alternatively offer a 10-degree forward angle and a 50-degree rear angle. These nozzles can be alternated on your nozzle bodies, and by pointing one "forward" then the next one "backward", you are able to produce four different angles of spray directed toward your target.

(h3) Best Practices for Managing Droplet Size

In addition to the nozzle type there are different techniques that you can employ to help manage the droplet size dispersed from your sprayer:

- Control the Pressure: Adjust the operating pressure to influence droplet size. Higher pressure creates finer droplets, while lower pressure produces coarser droplets.

- Mind the Weather: Pay attention to weather conditions. Spray on calm days to minimize drift and avoid spraying during high temperatures or low humidity to reduce evaporation.

- Boom Height: A higher boom level can increase the overlap and coverage, but it can also lead to more drift. A lower boom height reduces the chance of droplets drifting off target.

- Spraying Speed: Adjust your spraying speed as needed. Finer droplets may be less prone to drift at slower speeds, faster speeds might require larger droplets to stay on target.

- Regular Cleaning: Clean your nozzles regularly to prevent clogging and ensure consistent spray patterns. Use soft brushes or compressed air to avoid damaging the nozzle.

- Check for Wear: Inspect nozzles for wear and tear. Worn nozzles can produce uneven droplet sizes and poor spray patterns, reducing effectiveness. You can use spray pattern test paper or an electronic sprayer calibrator to evaluate your nozzles and identify any that are worn and not delivering a consistent spray pattern.Nozzles that overspray by 20% or more are considered worn and should be replaced.

Conclusion

Precision spraying entails a lot of complexity, and it all begins with choosing the right tip to achieve your desired droplet size. Understanding droplet size is crucial for successful spray application. The right nozzle can make all the difference when it comes to coverage, drift, and overall effectiveness. Navigating the complexities of droplet size and spray nozzle selection can be daunting. However, with some time and expert guidance, choosing the right nozzle for your specific needs can become a straightforward and stress-free process.

If you have questions or would like help identifying a sprayer nozzle to meet your needs, please reach out to our agriculture sales team!

Tech Ag & Industrial Sales

Shane Blomendahl is a tech sales veteran at Dultmeier Sales with over 10+ years of experience in liquid handling products covering several industries and applications.