It is no secret that there are quite a few options when it comes to sprayer tips. In fact, our Liquid Handling Catalog has over 30 pages dedicated to different spray nozzles! Fortunately, there is an international standard in place to ensure the consistency and performance of sprayer nozzles used in agriculture. This is crucial because nozzles need to perform reliably to apply pesticides, herbicides, and fertilizers effectively.

This standard, specifically known as ISO 10625, defines these specific nozzle characteristics: spray pattern, flow rate, and droplet size. The standard achieves this by implementing a numbering system that helps identify and categorize nozzles based on their performance characteristics and specifications.

Numbering System for Spray Nozzles

Now that we have the reasoning behind the numbers out of the way, we can examine what these numbers tell us.

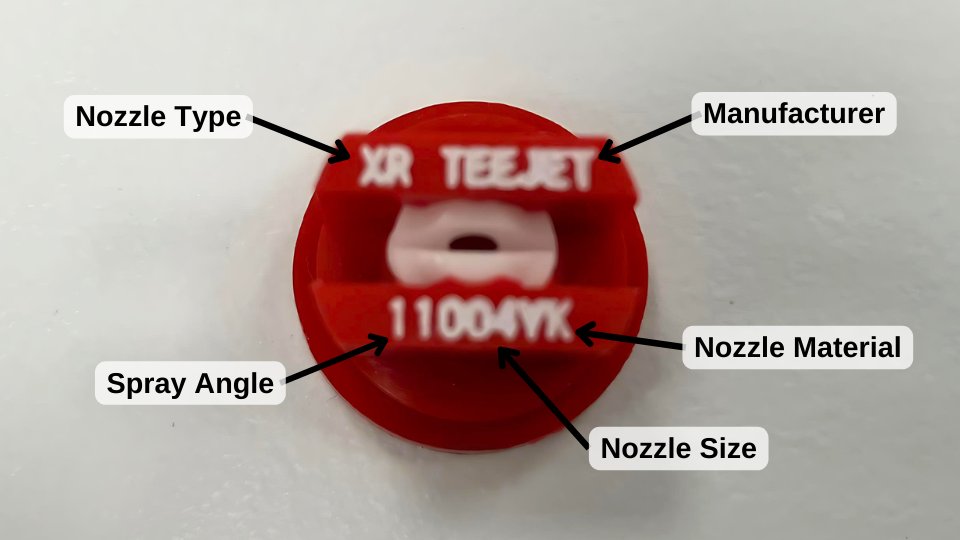

Each spray nozzle is assigned an identification code. This code may consist of letters and numbers. It provides the nozzle type, orifice size, spray pattern/spray angle, and material of construction.

- Nozzle Type: Manufacturer nozzle type/name. Denotes specific designs or features specific to this nozzle series such as extended range (psi), twin fans, droplet size, etc.

- Spray Angle: The numbering system specifies the angle of the fan produced by the nozzle. Nozzle spray patterns have a vital role in effective coverage. For more details, take a look at this chart that shows the theoretical coverage of nozzles at different angles and spray heights.

- Nozzle Size: The numbering system classifies nozzles based on their flow rate at a standard pressure (40 psi). This helps in selecting nozzles that deliver the correct amount of chemical per unit area.

- Material/Features: The final part of the code will include information about the nozzle material (e.g., brass, stainless steel, plastic). It can also note other nozzle features such as a specific shape or characteristic of the spray pattern.

Let's look at an example of nozzle numbering using an "XR 110-04 VK" spray tip:

Here is the breakdown of what each section of this sprayer nozzle number/code means for this specific nozzle:

- XR: This indicates the type or series of nozzle, in this case, the XR TeeJet, which stands for "extended range". Extended range refers to the wide range of PSI the nozzle will operate at.

- 110: Represents the spray angle in degrees. This particular spray tip, therefore, will spray at a 110-degree angle.

- 04: Indicates the flow rate. In this case, it signifies a flow rate of 0.4 GPM at 40 PSI.

- VK: Describes the material of the nozzle. "VK" stands for VisiFlo ceramic. This indicates that the nozzle tip is made of ceramic and follows the VisiFlo* color code.

*Just a quick note, VisiFlo was the color coding system started by Teejet to categorize different-size nozzles. This system was adopted by the ISO standard that is used today. The code assigns a color to each nozzle side:

Not all spray tips make it this easy. In some cases, spray tip numbers are not displayed as clearly on the nozzle face but instead may be labeled on the side or base of the nozzle. This variance in numbering location is because manufacturers often offer numerous nozzle types that vary in design, which of course further differs for each manufacturer.

Further complicating matters, some spray nozzle brands do not adhere to the ISO color coding system. To illustrate these differences, let's take a look at a few examples.

Example Sprayer Nozzle Numbers & Comparisons

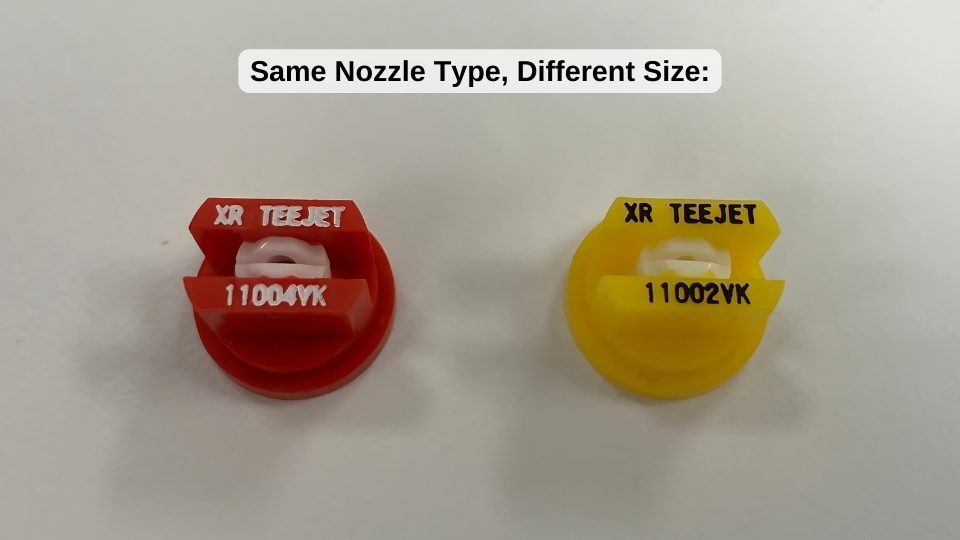

First, lets look at two nozzles from the same manufacturer and family/type. The only difference between the two is the sizes or flow rate:

The red nozzle is an 04 size and the yellow nozzle is an 02 nozzle.

The red nozzle is an 04 size and the yellow nozzle is an 02 nozzle.

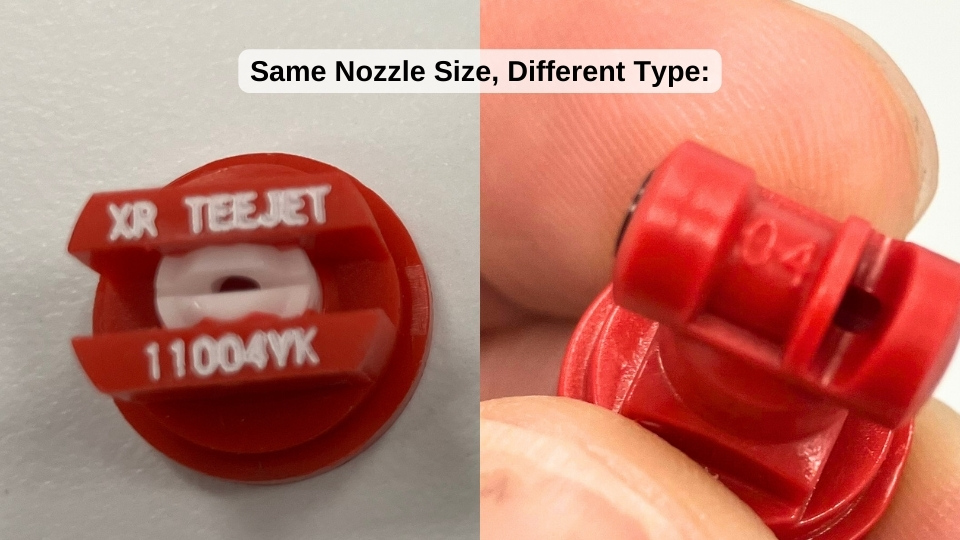

Now, sometimes the numbers are not this clearly displayed. Both of these are Teejet nozzles, but they are different types. You can clearly see the numbers on the XR spray tip but this other nozzle does not have the numbers listed in this form.

You can see that the nozzle does have an 04 on the tip, this along with the color indicates the size, as all red nozzles are going to be an 04 size. It does say Turbo and Teejet on the side but it is hard to see.

You will notice that there is no indication of the spray angle or the material. But, if we look up a TT nozzle in our catalog you can see that a Turbo TeeJet is going to have a 110-degree tapered flat fan and is made of polymer. This is an example where the manufacturer, because of the unique design of their spray tip, has only labeled the nozzle with the nozzle series (Turbo Teejet/TT) and the size (04).

Since all sizes within this family of nozzles share the same spray angle and material, the nozzle type is understood to stand in for this information without it having to be shown directly on the tip as with the XR nozzle. If you are uncertain or have a nozzle that lacks numbers clearly displayed on it, call us, we can help you!

In our next photo, we have two nearly identical nozzles. Same brand, same type, same size, and color; however, there is a significant difference in the spray pattern produced by each one. Once more, the numbers tell the story.

First Number: We know the first set of numbers is the spray angle. So here, the nozzle on the left produces an 80-degree fan, while the nozzle on the right will produce a 110-degree fan.

Second Number: We know this portion of the number signifies the size of the nozzle, which in this instance is 04 for both. We know this from the number as well as the color.

Letters: This is where things start to get interesting. The nozzle on the left does not have any prefix numbers (More on this in a bit). Conversely, the nozzle on the right is an XR tip. As we explained earlier, this means it is an extended-range flat fan tip. The final set of letters indicates the material of the tip, which for the nozzle on the left is VS (stainless) and on the right is VK (ceramic).

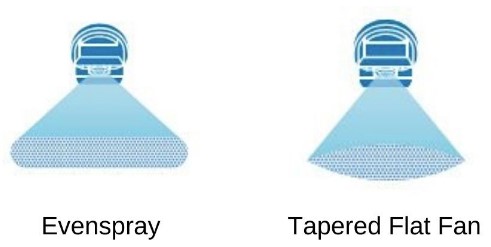

But what about that "E" before the VS on our first nozzle? This notes that the nozzle has a special spray fan. It is not the standard tapered flat fan found on most ag sprayer nozzles. Instead the "E" tells us that the nozzle produces an even spray pattern.

This one little letter makes these two nozzles very different. The XR nozzle will give you a tapered flan fan pattern. It applies the most spray in the center of the pattern, with less towards the edges. This is designed to overlap with other nozzles on a boom. An even fan spray nozzle, on the other hand, produces a uniform spray pattern across its entire width. This type is ideal for band spraying, where a consistent amount of spray is needed over a specific strip or band. Unlike the tapered flat fan nozzle, it does not taper off at the edges.

Image from Teejet.com

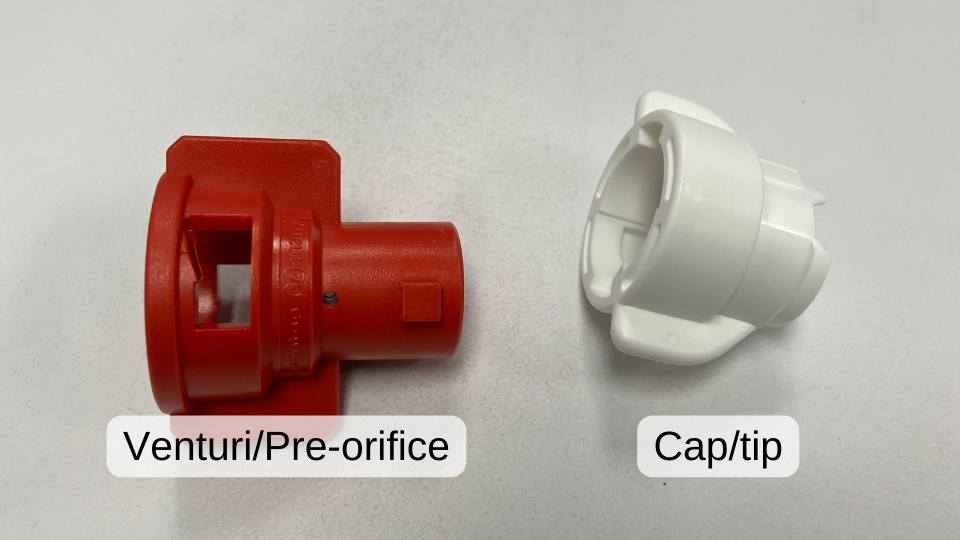

For our last comparison, let's look at Greenleaf TurboDrop nozzles. These nozzles all consist of two pieces that each have different numbers on them. This can lead to some confusion. The reason for the two sets of numbers is that they are made up of two sections: a venturi pre-orifice and a tip/cap.

Below we have a TDXL11004 TurboDrop series nozzle. The venturi, which is the red portion, has a size number on the side. For the TDXL11004, that number is TD 04. This follows the same color code and size code as other flat fan nozzles.

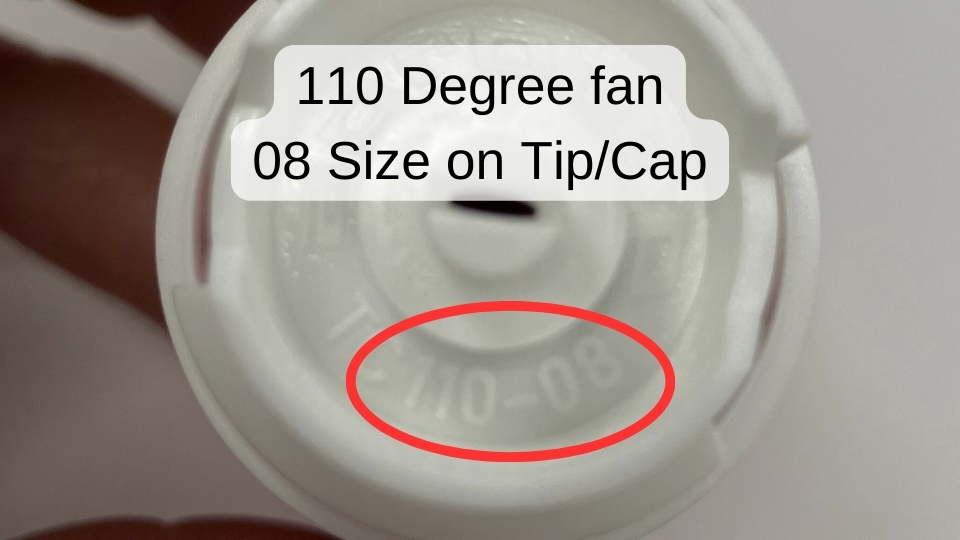

The tip/cap, which is white for this particular nozzle, will also have a number. You will notice that our number is 110-08 and the color is white. If you remember, a nozzle with 04 in the number will have a flow of 0.4 GPM. So what is this 08 tip doing on a nozzle that says it is rated for 0.4 GPM?

Greenleaf TurboDrop nozzles are designed to reduce drift and still offer excellent coverage. Their two-piece design pulls air into the droplets to create a consistent droplet size. The venturi or pre-orifice controls the rate while the tip/cap produces the fan. Consider the TDXL11004, On its own the white 08 tip/cap could be used as a standard 11008 spray tip that will produce finer droplets.

When combined with the venturi, though, it becomes an effective air-induction nozzle. The tip is double the size of the pre-orifice and this difference is what helps pull air into the nozzle resulting in larger air-filled droplets.

Using These Numbers: Spray Nozzle Charts

Once you understand spray nozzle numbering, you'll be able to better choose the right nozzle for your specific application. Identifying the number on the nozzle is just half the battle. You will also need to know how to read a spray nozzle chart to compare nozzles and examine the different characteristics of each type.

A spray nozzle chart provides all the necessary information you need to determine how a nozzle will perform under various operating pressures. These charts are provided by the nozzle manufacturers, TeeJet, Wilger, Hypro, Greenleaf, etc. Nearly all spray charts will display the following information:

- Flow Rate: The amount of liquid delivered per minute at a specified pressure, usually measured in gallons per minute (GPM) at 40 psi.

- Spray Angle: The width of the spray pattern produced by the nozzle, measured in degrees.

- Droplet Size: Classification of the droplet size produced, which can range from very fine to extremely coarse.

- Operating Pressure: The range of pressure that the nozzle will perform as intended, usually measured in pounds per square inch (PSI).

- Application Rate: The amount of liquid applied per unit area, expressed in gallons per acre (GPA).

Sprayer Nozzle Chart Example

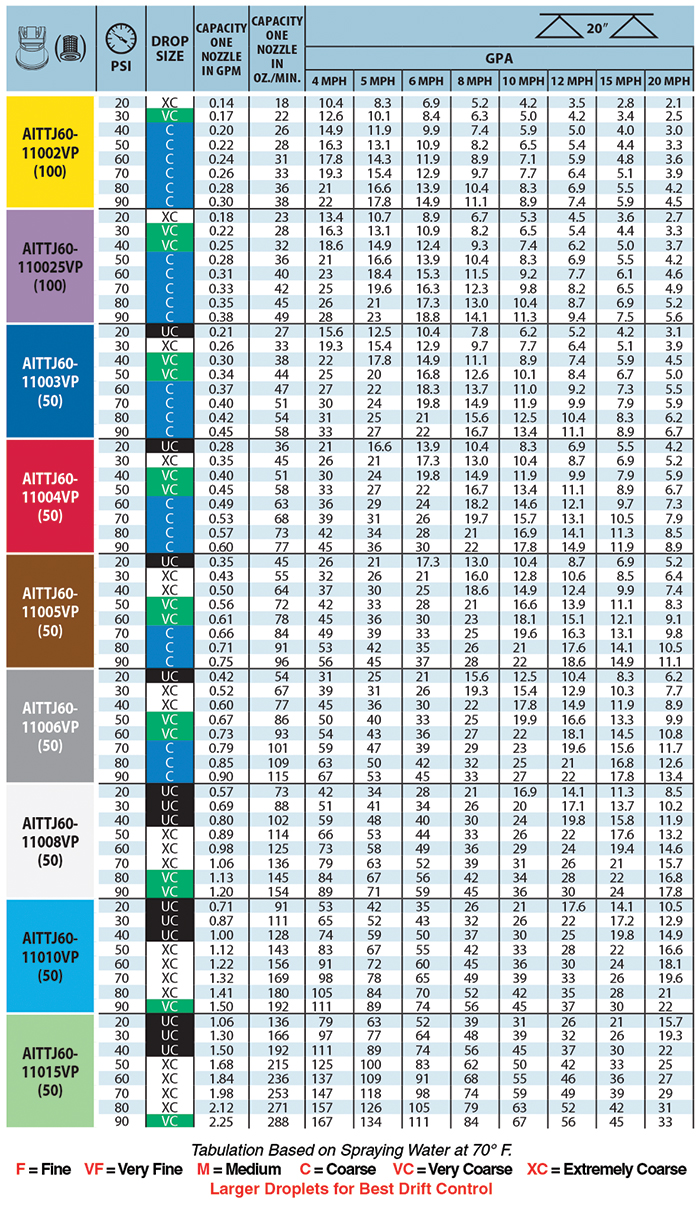

This is a nozzle chart for the Air Induction Turbo TwinJet Nozzles. You can see that the nozzle capacity (flow rate), droplet size, and GPA is displayed at various pressures:

Spray nozzle charts warrant a more detailed discussion to thoroughly understand them. While we won't get into those details in this guide, for more information check out this article on how to use sprayer nozzle charts.

Spray Nozzle Selection Tools

Many spray nozzle manufacturers now also offer electronic spray tip selection tools that offer nozzle recommendations based on your specific application inputs. These tools make nozzle selection easy, but a basic understanding of the numbers behind the nozzle is still important when using these tools:

Conclusion

Understanding the numbering system for spray nozzles is crucial for selecting the right one for your application. The ISO 10625 standard provides a clear and consistent method to identify and categorize nozzles based on their performance characteristics.

Dultmeier handles a large quantity of TeeJet, Wilger, Greenleaf, and Hypro sprayer nozzles in stock and ready to ship. If you need assistance sizing and selecting a nozzle, don't hesitate to reach out for expert help.

Tech Ag & Industrial Sales

Shane Blomendahl is a tech sales veteran at Dultmeier Sales with over 10+ years of experience in liquid handling products covering several industries and applications.