The Chemical Transfer Equipment Industry Challenges

A long-standing challenge within the chemical transfer equipment industry has been rugged electronics that can stand up to harsh environments. In the past five years, one company stepped up, in a big way, to address this issue. The issue I am hinting at is the necessary ruggedness required by the agricultural industry for chemical pumps and meters. End users in the chemical transfer industry have, in the past, wrestled with the challenge of finding a meter/pump combination that is able to take the necessary beating the agricultural industry throws at it - while maintaining accuracy and performance attributes.

The use of products that lack ruggedness and robust design results in decreased efficiency, inaccurate readings, poor use of time, and higher maintenance/repair costs. Every single point I just hit on directly increases the end users' cost. Dura Products has and will continue to help the end user lower those costs by offering the market place something it was so desperately seeking - Rugged Quality Products.

Dura Products & Lasting Value

Dura Products has decided to step up and address this concern that has challenged the industry for years now. From simple in-line meters to diaphragm pumps to complete pumping systems - Dura has ensured quality control on their products and they genuinely care about how that quality is perceived by end users.

At the time of this writing, Dultmeier Sales has been a distributor for Dura Products for roughly one year. Dura Products runs the extra mile, in regards to, ensuring quality in their products has helped them stand out in the market place. We are starting to see more and more customers gravitate towards Dura Products. Are they offering sweet incentives to purchase their products? No, they are not. What they have done is supply the market place with rugged and quality products and tremendous service to back up those products.

Less downtime, more accurate readings, improved ruggedness, and increased quality are staples the end user can expect when running a Dura Products item. This company shows an insatiable desire to deliver quality to the market place. That is what I have witnessed in our short and blossoming relationship with Dura Products.

Dura Products Offering Package

Ag Dura-Pump Features

Dura-Meter: True Ruggedness

The meter is the user interface to 76% of Dura Products' Ag Systems packages. Dura Products has addressed a major issue in the design of this meter. That issue being the majority of meter failures result from moisture and abuse. Now, let's be real - the agricultural industry isn't going to play any nicer with a $50 widget than it is with a $500 widget.

By acknowledging that simple and known fact, Dura Products justified the need for a rugged meter that was able to withstand the beating thrown at it by the agricultural industry - and still maintain the ability to accurately measure chemical in the field. Thus the Dura Meter was born.

Key Benefits of the Dura-Meter

- 100% Moisture Sealed Circuitry

- Faceplate Made of Impact Resistant

- Easy-to-Calibrate

- Menu Driven, Backlit Display

- Plumbed for Both In-Line and 90 Degree Applications - no additional adapters needed

- Extended Battery Life: 4 "AAA" Batteries

- Power Life Constantly Displayed

- Features 2 Year Warranty

- You Can Use the Face Plate to Fit a Flowserve/Scienco Meter - the bolt hole patterns match between the two meters

Dura-Pump Easy Caddy

The Easy Caddy system is an efficient and clean way to keep your chemical distribution system tidy, as well as, protected. The Easy Caddy keeps the pump directly above the IBC shuttle valve - this is beneficial as forklift operators need to only be concerned with one side of the shuttle. All the equipment that could potentially be damaged is contained on one side of the shuttle and kept neatly organized.

Conversely, if the end user fancies a top mount or, the more portable, ground version - those options are also available. We have seen many retailers and growers, alike, gravitate towards the side mount style, recently.

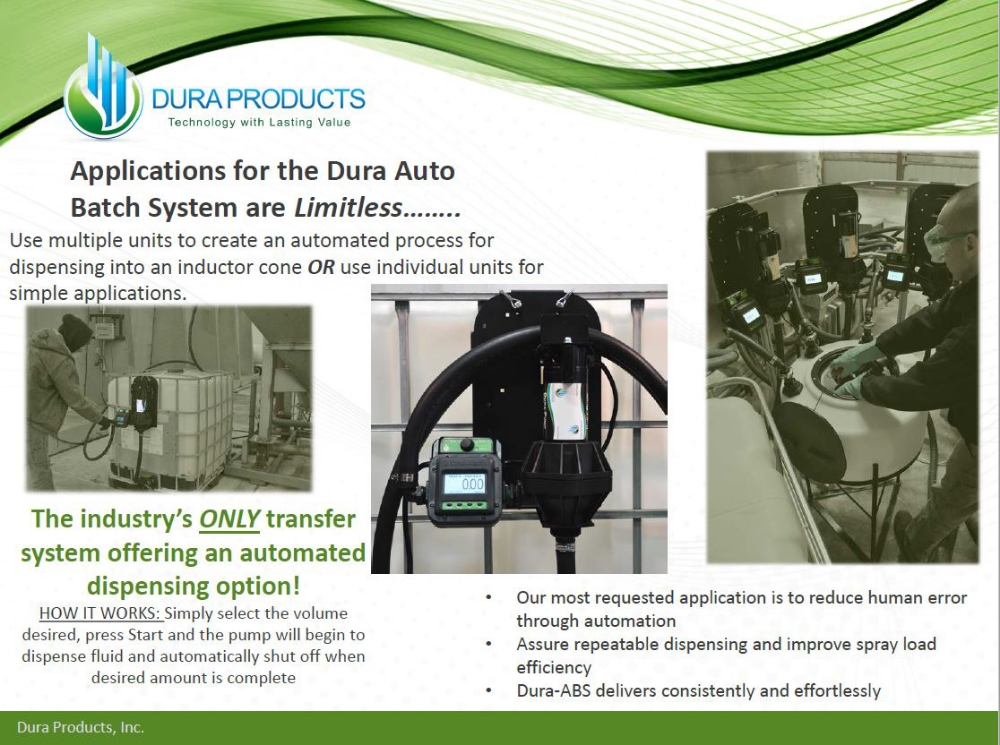

Dura Auto Batch System - Limitless Opportunities

The Auto Batch system allows the operator to remotely program and distribute chemical. Again, the Dura Meter is the main interface for this system. The Auto Batch system does have a manual mode if you wish to top off a shuttle or container. The system can be reverted back to automated mode at the flip of a switch.

Shop Dura Auto Batch System Now

Chemical Compatibility

Dura Products not only ensures greater quality in their products, but they want to make sure that customers are educated on proper chemical compatibility. You can have the greatest pump/meter combination in the world but if you are running a product that is incompatible with the elastomers - you are going to ruin the equipment.

For this reason, Dura Products relies on distributors and end users, alike, to confirm chemical compatibility. Dura Products offers their pump and meter systems in three stock elastomer options: EPDM, Viton, and Silicone. Check out a previous post that we wrote up on the product trade-named Resicore and the importance of chemical compatibility.

Here is a link to a wonderful Chemical Compatibility Chart that Dura Products has published.

It's extremely reassuring to know that a manufacturer, not only puts this much emphasis on quality assurance but an equal emphasis on chemical compatibility. Marketplace education is a huge focal point for the Dura Products team, as it is with the Dultmeier Sales team.

2 Year Maintenance & Warranty Program

So, now that we have discussed all the wonderful benefits of Dura Products physical attributes in their products - let's touch on their two-year warranty program for pumps and meters. All Dura Products items have a two-year service warranty program. If it breaks or malfunctions - Dura Products wants it back. They will make the repairs and then send out the refurbished unit(s). This further helps maintain their process of quality control.

It's extremely reassuring to work with a manufacturer that exemplifies this commitment to producing and ensuring quality products. Equipment that falls under warranty period and parameters will be repaired, or replaced, and returned at no cost to the customer.

Secondly, the two-year maintenance program allows customers to coordinate a return to Dura for refurbishment of pumps and meters - at no charge. Within this program, Dura Products will triple rinse pumps and/or meters to ensure no cross contamination is possible. All equipment will be taken apart and evaluated to ensure seals, gaskets, and internal components are operationally acceptable.

During this process, any parts that are still under warranty will be replaced at no charge. If any parts need to be replaced, that are not under warranty (i.e. broken housing, damaged parts, chemical compatibility issues, cut cords, etc.), they will be replaced and charged to the customer with NO additional labor charges. Lastly, the customer will be notified of all findings associated with cost and ETA of when the equipment can be expected back to the end user. This is another facet that truly sets Dura Products apart from the rest of the pack.

This concludes our Manufacturer of the Month highlight. We hope that you enjoyed this write up on Dura Products and sincerely hope that you stop back soon. Take care and be safe out there.