A Look Back in Time - The History

In order to completely understand the powerhouse that TeeJet has come to be, we first must look back in the annals of time and address some of the major milestones that helped elevate the Spraying Systems brand to the worldwide leader of spray equipment. So, let's dive right in and look at the inception of the company.

Spraying Systems Co. was co-founded in 1937 by two European immigrants to form the basis of the dynasty that exists today. The company enjoyed a rather humble start in a small 600 square foot garage in Chicago, IL. I bet those two men never imagined, in their wildest dreams, how the company would evolve and grow - and what their company would achieve over the next eight decades.

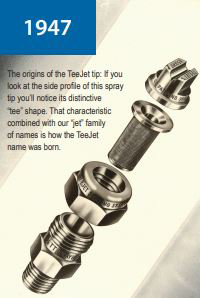

TeeJet is Born

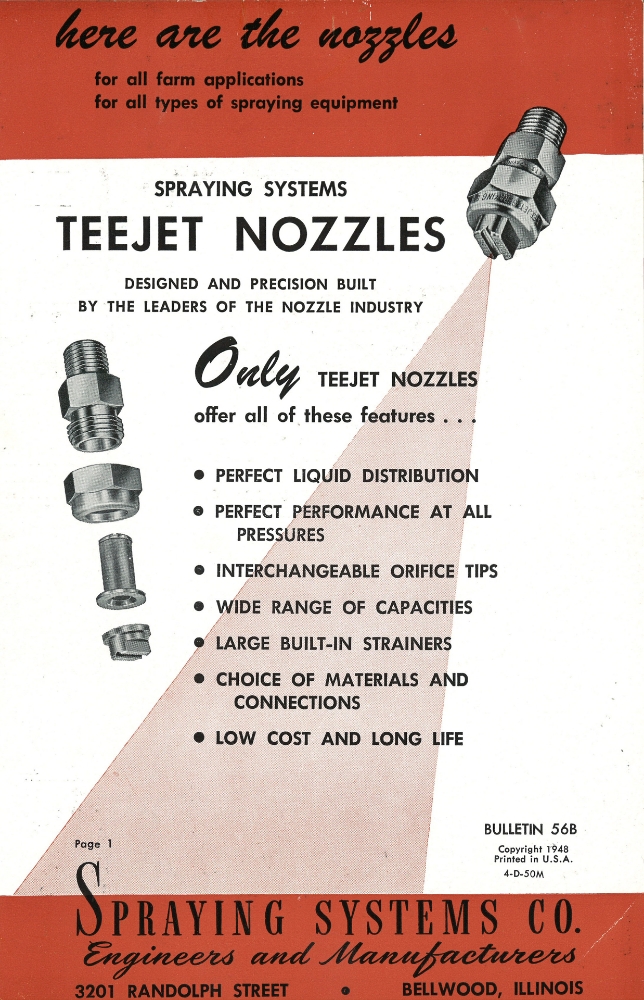

In 1947, the origins of the TeeJet spray tip were conceived. The side profile of the first spray tip embodied a "tee" shape. This combined along with the "jet" family of names is how the TeeJet name came to be. For many years, the industry only required two sizes of spray tips. One must remember that the agricultural industry was still using manure and egg shells as the primary means of fertilizer up until the late-1950s.

One of Dultmeier Sales' long time employees, Bob Hansen, joined the industry in the early 1960s and recalls that the TeeJet family had just two spray tip sizes at the time - a 5 gallon and 10 gallon capacity. Both spray tips were offered only in brass. We will circle back to the expansion of fertilizer distribution later on in this write up and how that quickly elevated TeeJet to Goliath status in the spray industry. For the time being, let's get back to the chronological progression of the company.

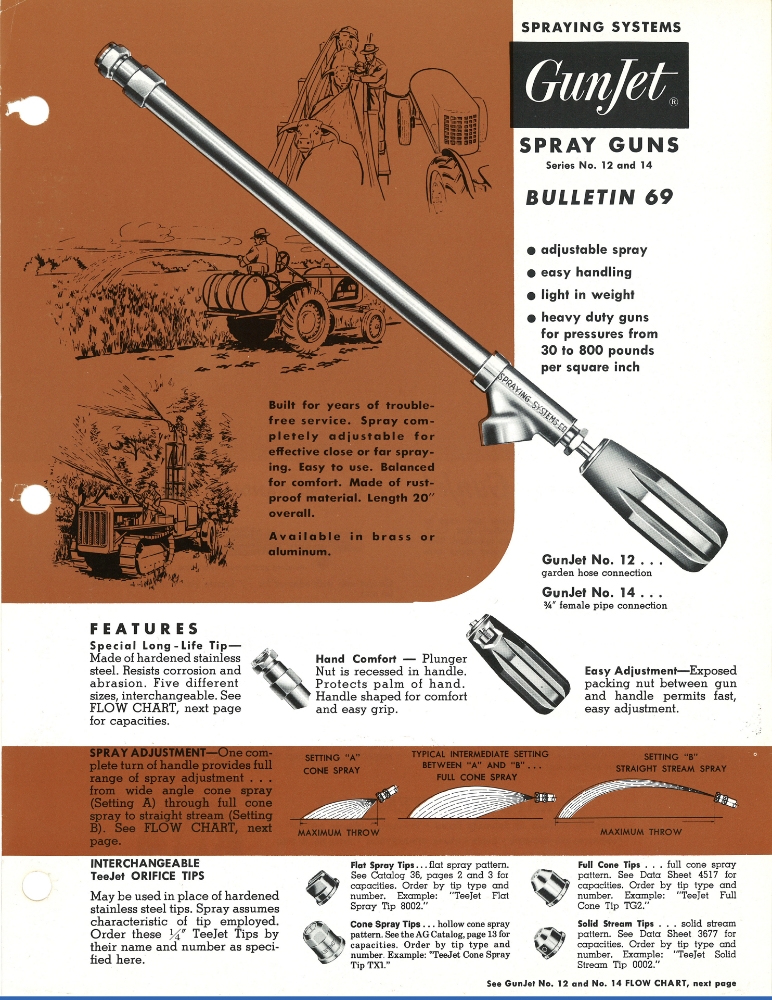

GunJet & TeeValve Become Staples

In 1952, TeeJet introduced their first spray gun product line. Models such as the AA43 and AA2 were the first introductions. Today, farmers have a much wider range of trigger and twist-handle guns for spot-spraying applications. Many of those products can be viewed here.

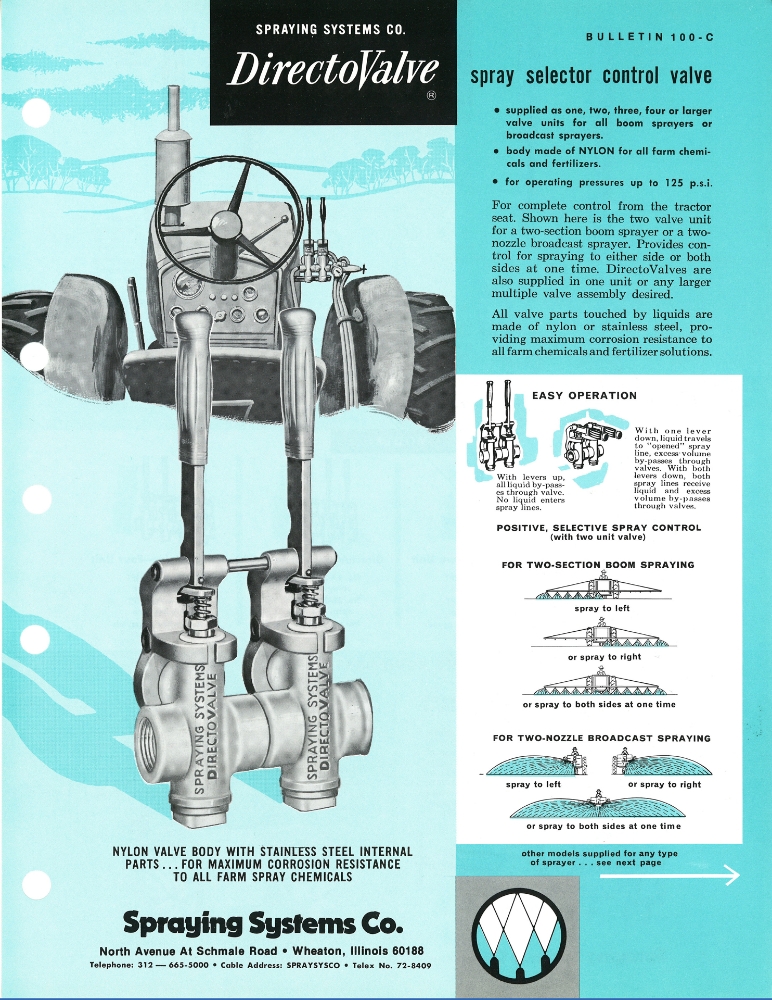

Next up was the introduction of the TeeValve in 1956. This was revolutionary in the agricultural spray industry as it allowed an operator to remotely control three boom sections on a sprayer. The compact design quickly gained popularity and became a staple in the agricultural industry. This product was so well-built and engineered that it is still used today. You can view this product here.

An offshoot of the TeeValve is the DirectoValve. This product has been slightly modified over the years. The neat feature of this product is that is extremely versatile - it can be banked together to create a manifold, or it can be used alone as a singular valve. However, this is another testament to the superb engineering and functional design from Spray Systems Co. - many of their products from the mid-1900s are still widely popular within the industry. It's neat to see the old archive below and compare it to today's version. The electric version of the DirectoValve can be viewed here.

Agricultural Spray Technology is Rapidly Expanded

In 1968, Spray Systems Co. designed the first electronic spray pattern analyzer in-house. This innovative piece of equipment allowed the company to drastically improve qualities of the expanding TeeJet family. This technology allowed the company to more accurately measure droplet size which is a critical component of nozzle design and functional application.

By now, the agricultural spray industry had been experimenting with a new fertilizer called anhydrous ammonia, or NH3, for about seven years. This wonderful fertilizer helped increase growth rates and yields of crops. Not only did it improve crop growth rates - but also weed growth rates. The TeeJet family had positioned itself superbly.

2,4-D and DDT were the primary chemicals used in the agricultural industry up until the introduction of anhydrous ammonia as a prominent fertilizer. Once weeds began to expand rapidly, as a result of this wonderful fertilizer - new formulations were necessary to keep them at bay. With new chemical formulations came the demand for new spray nozzles.

Chemical applications rapidly expanded over the next decade to combat the exploding growths of weeds - along with crops. The industry needed to quickly kill weeds to ensure that crops received as much of the fertilizer nutrients as possible. Let the weeds live and they starve crops of precious, and expensive, input resources. Rather abruptly, the industry changed its practice to combat weeds from cultivation equipment to liquid applications in the form of various chemicals. The TeeJet family was a natural fit to help fuel a major industry boom.

1970s & 1980s

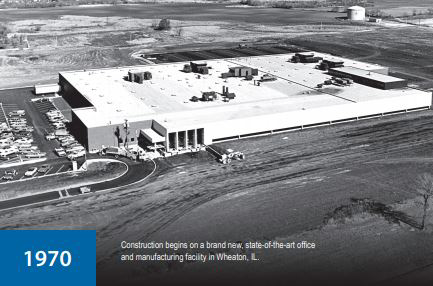

This period embodied an era of rapid growth and expansion for Spraying Systems Co. 1970 marked the beginning of construction on the state-of-the-art office and manufacturing facility in Wheaton, IL. In 1976, LH AGRO was founded in Denmark by two gentlemen named Larsen and Henning. The company's first product was a grain loss monitor.

TeeJet entered the 1980s with a bang. The introduction of the Quick TeeJet system again revolutionized the agricultural spraying industry - and the rapidly growing carwash industry, as well. The 1/4-turn quick attach cap and body system substantially reduced the effort required to install or change spray tips. This system also provided an automatic spray pattern alignment across the boom for optimum distribution.

As Dultmeier Sales evolved into the carwash industry, Mike Hansen the Wash Division Manager, greatly relied on the partnership of TeeJet to help offer a solid product line for soap and wax application in self-serve carwash industry. And the Quick TeeJet product line helped Dultmeier Sales do just that. As the agricultural market struggled throughout the 1980s, the carwash industry helped to diversify both Dultmeier Sales and Spraying Systems. Even today, as you move through more sophisticated carwashes - you will see the Quick TeeJet products on many of the stationary boom structures.

The Quick TeeJet is introduced in 1981

In 1983, Midwest Technologies (Mid-Tech) was founded in Springfield, IL. Mid-Tech quickly became recognized as a pioneer of direct chemical injection systems and quickly advanced the Spraying Systems brand into the electronic sprayer & spreader control markets - and eventually into GPS guidance systems. Mid-Tech joined the TeeJet family in 2000.

In 1984, the LH1200 was launched in Europe and marked the entrance of the LH AGRO product offering into the sprayer control market. LH AGRO would eventually become a member of the TeeJet family in 2000 with a focus on electronic controls and precision farming equipment. Then, in 1985, the next major introductions into the TeeJet family came with the VisiFlo and XR TeeJet flat fan tip series.

The VisiFlo system incorporated color-coded plastic tip bodies with a stainless steel orifice. End users were able to quickly identify the tip capacity based upon the color of the spray tip - another revolution within the spray industry. The VisiFlo color-scheme quickly became the industry standard and was adopted by ISO as the worldwide standard in agricultural tip capacity identification.

The XR Flat Fan spray tip series was created based upon new manufacturing techniques that enabled the production of an orifice that offers excellent pattern formation and spray distribution across a wide range of operating pressures. The XR tip series has become the standard agricultural spray tip and continues to be one of the highest selling spray tips manufactured today.

Retro XR TeeJet and VisiFlo Bulletin

The 90s - Advanced Controls & Air Induction Spray Tips Introduced

The 1990s brought about further product diversification and advancement for Spraying Systems Co. The company acquired the ECOSpray product lines in 1993 which further expanded its offering in sprayer controls. Then, in 1995, the QJ360 nozzle turret was introduced. This multiple outlet nozzle body quickly found favor with OEMs and farmers, alike. TeeJet knocked another one out of the park with the simple design and easy use/installation of the QJ360 series.

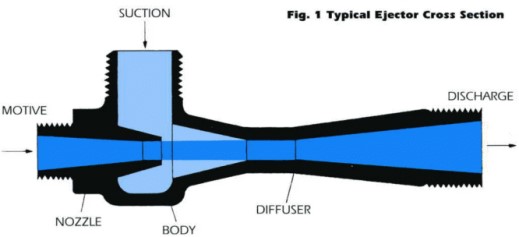

Then, in 1998, TeeJet entered the air induction spray tip into the marketplace with the launch of the AI tip series. The combination of a pre-orifice and venturi produces large, drift-resistant droplets. TeeJet felt it was necessary to develop this product due to the continued growth in the use of non-selective herbicides like Roundup. These types of chemicals drastically increased the demand for products that reduce spray drift.

The Next Century - GPS Guidance & Precision Technology

The turn of the century lead to further product enhancements and new technologies that allow end users to become more accurate and more efficient. In 2000, the Mid-Tech Swath XL lightbar launched and marked the entrance of TeeJet into the growing GPS guidance market.

Then, in 2006 the CenterLine 220 revolutionized the GPS market - it brought GPS guidance functionality to every farmer due to the simplicity, reliability, and affordability. Easy operation paired with quick installation make this product appealing and quickly grew its popularity. You can view the current GPS guidance products from TeeJet here. Another important introduction in 2006 was the Turbo TwinJet spray tip. This was the next generation as it offered a twin spray pattern with superior drift control. Market demand for twin spray patterns experienced a rebirth during the early 2000s and TeeJet sought to capitalize on this trend.

2009 came along with another large advancement in the GPS market with the introduction of the Matrix guidance console. This product features a 3-D touchscreen interface and brings GPS guidance with live video to form the patented RealView guidance over video feature. The Matrix quickly became the preferred platform for GPS guidance. Additionally, this product allowed end users to leverage new technology called FieldPilot. Which further enhanced efficiencies and helped to reduce waste through features such as auto-steering and automatic boom section control. TeeJet GPS Guidance Systems, including the Matrix 430 can be viewed here.

The Aeros 9040 field computer was introduced in 2012 and emerged as the most powerful controller offered in TeeJet history. This field computer is targeted towards the self-propelled OEM market. Functionalities include GPS guidance, automatic rate control, automatic boom section control and droplet size monitoring.

In 2017, TeeJet introduced a couple more key products. The TTI60 TwinJet and the DynaJet Flex 7140. The TTI60 TwinJet tip/cap combined flat spray patterns and ultimate drift control capabilities of the proven TTI spray tip. The DynaJet Flex 7140 brought Pulse Width Modulation (PWM) nozzle control to the TeeJet family of electronics. The unit boasts ISOBUS compatibility for seamless integration into a wide range of control systems and machines.

The Dultmeier Sales-Spraying Systems Co. marriage goes back many years. Back to the days of just two brass spray tips and the introduction of anhydrous ammonia as a fertilizer into the agricultural industry. It's nostalgic to look back and see how far we've come. But we are eager to see what the future holds.

We hope you enjoyed this manufacturer highlight of Spraying Systems Co. - TeeJet. Stop by in the future or check out more posts here. As always, if you enjoyed this post - please give us a share.