Whether you plan to use a starter fertilizer or soil biologicals, applying these liquids requires a proper pump. There are many different options available which makes selecting the best option important. Fortunately, most pumps can work in several different applications, the key is identifying a pump that will best handle your liquid, deliver your desired application rate and pressure to fit your system, and provide long-term value.

The sales crew at Dultmeier has been helping to set up planter fertilizer systems for decades. In this guide, we'll explore the various pump options for planters, delving into the strengths and weaknesses of each. From the high-volume capabilities of centrifugal pumps to the precise metering of piston pumps, and everything in between, we'll cover all you need to know to find options that will best meet your needs.

How to Choose a Fertilizer Pump for a Planter

When using a pump on a planter to apply fertilizer your focus should be on accuracy and reliability. A variety of different pumps can accomplish this, but they achieve this through various means, so that means there are pros and cons to each different type.

What to consider when comparing different types of fertilizer pumps:

- Durability: Pumps are made from different materials with varying degrees of resistance or durability when used in rugged conditions with corrosive & abrasive fertilizers.

- Serviceability: Some pump types are easier to rebuild than others.

- Flow Rate: There are pumps available to produce varying flow rates, so first determine your required flow rate per minute and identify a pump that will deliver this rate plus some cushion for agitation and increases in speed or application rate.

- Priming/Suction: Consider the pump's priming capabilities, especially in situations where it needs to draw fertilizer from a tank set below the pump level.

- Precision: Assess how accurately the pump can deliver the specified amount of fertilizer. Precision is crucial for consistent application and to avoid wastage or crop damage.

- Compatibility: Ensure the pump is compatible with the type of fertilizer being used. This includes checking for chemical compatibility with the fertilizer to prevent corrosion.

- Drive Type: Pumps can be driven by different means, such as PTO, hydraulic, or electric motors. Consider the available power sources on your equipment and how the drive type fits into your existing setup.

- Complexity: Some pumps are more complex in design, requiring more expertise to install and maintain. Simpler designs may be more user-friendly but could lack advanced features.

- Cost: Balance the upfront cost of the pump with long-term operational costs, including maintenance, repairs, etc. A more expensive pump may offer better durability and efficiency, reducing overall costs in the long run.

- Fit: Ensure the pump fits physically and functionally with your current equipment. This includes mounting options, connections, and space availability on your planter or tractor.

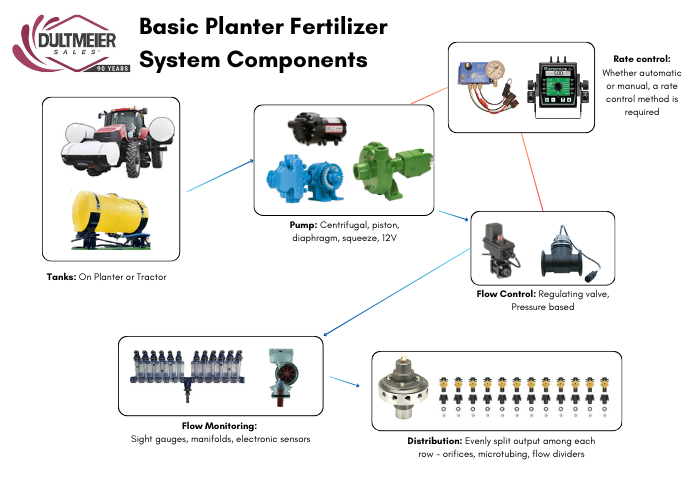

Consider the Overall Fertilizer System

Pumps are just one part of the entire fertilizer application system. The plumbing, control valves, nozzles, etc. work together with the pump to meter and distribute the liquid. The type of pump you use will affect how the rest of the system needs to be put together. The best pump for you will depend on the specific things you need your system to do.

Choosing the right pump requires that you know what type of system you desire. You might desire simplicity and ease of operation, or you might need more precision and the ability to vary your rate automatically. These pump features along with the available drive type and your budget will ultimately determine the pump that will work best.

We go into greater detail on the overall fertilizer system in our guide to planter fertilizer setups, but here are some of the main types of systems and how they differ:

- 12-volt Pressure Based: a 12-volt pump controlled via a rheostat

- Ground Drive: pumps driven by planter wheel or ground drive assembly, application rate is maintained automatically as planter speeds up or slows down

- Automatic Rate Control: The flow rate is automatically controlled with a rate controller, regulating valve, GPS/speed sensor, and flowmeter. Also allows for rate changes from the cab.

- PWM: automatic rate control with rate controller; pump motor speed is adjusted with a PWM valve or motor instead of using a conventional regulating valve.

Different Fertilizer Pump Types Used on Planters

Many of the types of pumps used on planters are similar to those used on a sprayer. There are also pumps designed specifically for planters/toolbars such as squeeze pumps and ground-driven piston pumps. You can see more specific details in our guide to sprayer pumps, but the basic types are:

Let's examine each type of pump used and identify the scenarios they work for applying fertilizer on a planter.

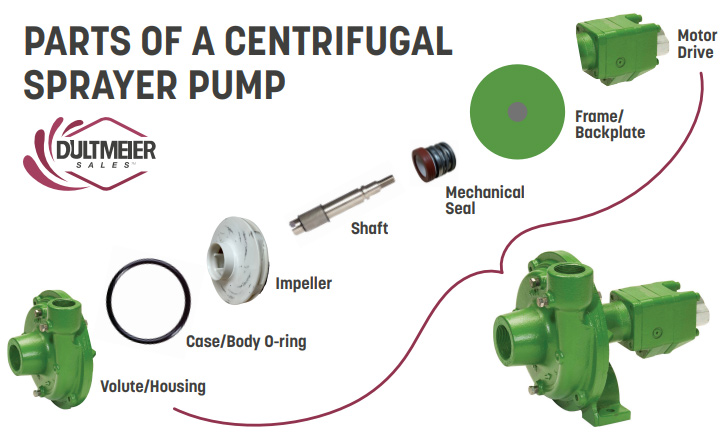

Centrifugal Pumps

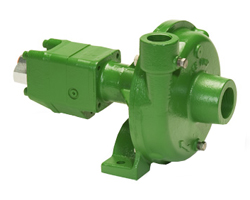

The same type of hydraulic-driven centrifugal pumps used on sprayers can be used as a fertilizer pump on a planter. Centrifugal pumps are available that can provide flow rates well over 200 gallons per minute. If you have hydraulic outlets available, then they are a great option, especially for higher volume rates and larger planters.

For example, if you have a 24-row planter and want to apply a rate of 50 gallons per acre at 5 mph, you need more than 20 gallons per minute from your pump. So, at a minimum, you want a pump that can deliver this flow rate. To be safe you would want a pump that can deliver more than this to account for increases in speed, rate, and agitation.

Now, when these pumps are used on a sprayer, they are generally handling a liquid that is mostly water. On a planter, you are likely dealing with 100% fertilizer or a diluted solution of fertilizer, water, etc.

To handle the abrasive and corrosive nature of fertilizers, stainless steel pumps are recommended. Cast iron and poly will work, but they typically do not last as long. While stainless is usually the best option, it does depend upon the specific type of fertilizer or liquid being used. Many centrifugal pump manufacturers, like Ace and Hypro, offer a severe-duty mechanical shaft seal that is made to hold up better to abrasive material. Standard seals will work, but again, they may not last as long.

It is always vital with a standard centrifugal pump that you don't run it dry. This will knock out the seal quickly. However, there are "wet seal" centrifugal pumps that are protected from running dry. These pumps have a reservoir with a coolant/anti-freeze to lubricate the pump so if the pump is starved of fluid, the seal is still lubricated.

Pros of Using Centrifugal Pumps for Planter Fertilizer Application:

- High volume

- Easy to maintain and rebuild

- Good for 2x2

- Long service life, especially stainless steel

Cons of using a centrifugal pump on a planter:

- Hydraulic outlets needed

- Cannot run dry (unless wet seal pump)

- Straight centrifugal pumps are not self-priming and are limited in where they can be installed.

System Requirements When Using a Centrifugal Pump:

Centrifugal pumps need a mechanism to control the flow. Typically, this requires a flow meter, regulating valve or PWM hydraulic motor, along with GPS or speed sensor, and a rate controller. Centrifugal pump setups are relatively more expensive than some other setups.

For more information on the overall fertilizer setup including controls, monitoring, and metering, refer to our full guide to planter fertilizer systems.

Centrifugal Pumps Options for Planters:

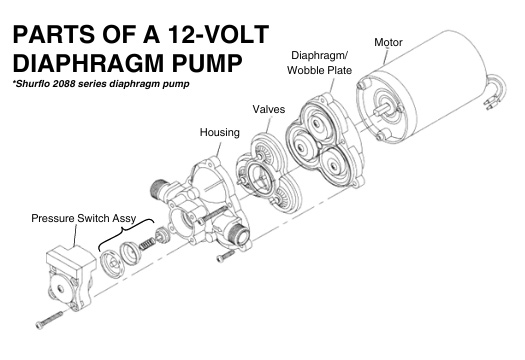

Electric Fertilizer Pump for Planter: 12-Volt Diaphragm Pump

One of the most cost-effective ways to get a starter fertilizer applied is with a 12-volt diaphragm pump. They are especially convenient for someone wanting to add a simple setup to a planter that can be installed easily. 12-volt diaphragm pumps do have some limits. They have a maximum effective flow of about 3-6 GPM. This means they are suited for application rates of up to about 10 GPA for smaller planters (6-12 rows) and about 5 GPA for larger planters (24 row+).

12-volt pumps are small and lower cost than other types of pumps. They can be easily installed about anywhere you can supply 12-volt power. It is also easy to adjust the pump output using a rheostat motor controller. This simple controller lets you increase or decrease the pump output from the cab as you speed up or slow down.

Advantages of 12-Volt Diaphragm Pumps:

- Low cost relative to other pump types

- Simple and easy to install

Disadvantages of Diaphragm Pumps for Fertilizer:

- Lower flow compared to other pump types

- Typically do not last as long as other pump types

System Requirements for 12-Volt Diaphragm Pumps:

A complete setup requires a pump speed controller, flow monitors, and orifice discs to regulate the output of the pump and apply the correct amount of liquid. This is one of the simplest and lowest-cost ways to apply a starter fertilizer in-furrow.

Dultmeier offers 12-volt pump kits that include the pump, monitors, speed controller, and plumbing components to install on your planter. Be sure to check this page for a complete list of the kit components. Don't worry we can make any changes to the kit if you need it!

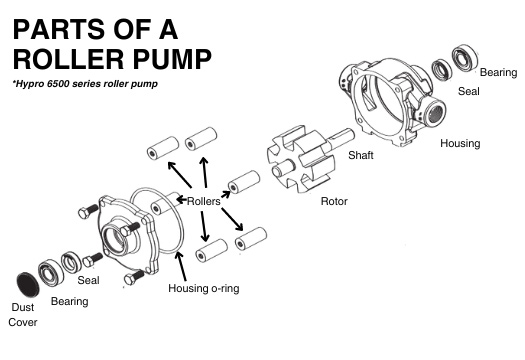

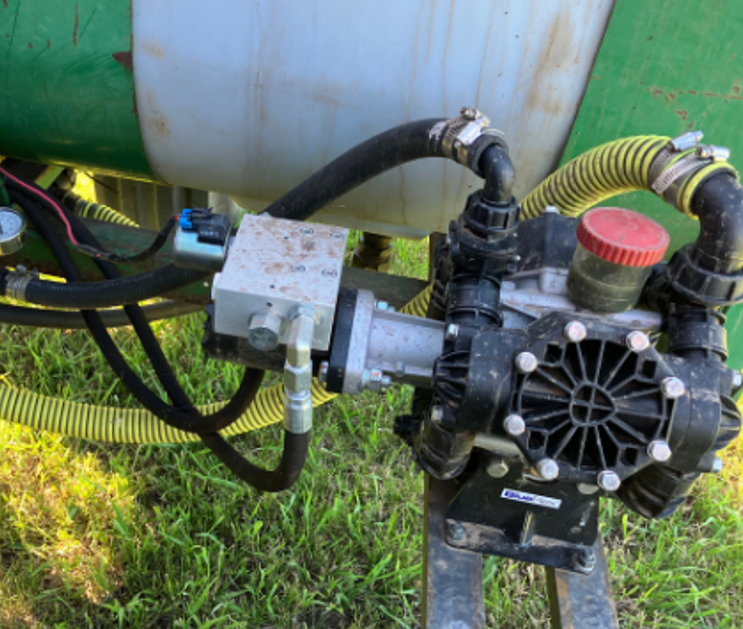

Hydraulic Driven Diaphragm Pumps

12-volt electric is not the only type of diaphragm pump that can be used to apply fertilizer. A larger, high-pressure diaphragm pump is another option that delivers more flow and much higher pressures than the small 12-volt motor versions.

These pumps have excellent suction lift, meaning more flexibility where they are installed vs centrifugal pumps that need to be flooded. These pumps can handle thick and viscous fertilizers with high solid content. The gearbox is lubricated with oil. There is virtually no concern if you run the pump dry.

This type of diaphragm pump can be driven via a number of different means. Ground drive, engine, etc. The most common option on planters is a hydraulic motor. This may be a conventional hydraulic motor or PWM controlled motor.

Advantages of Diaphragm Pumps:

- High volume potential

- Higher pressure capability compared to other pump types

- Self-priming

- Can run dry

- Ability to handle viscous products

Disadvantages of Diaphragm Pumps for Fertilizer:

- Lower flow compared to centrifugal pumps

- Requires pressure relief valve

- Routine maintenance required

Diaphragm Pump System Requirements:

A diaphragm pump setup will require a rate controller with a flow meter and a regulating valve to control the amount of fertilizer you apply. Diaphragm pumps with PWM hydraulic motors are also available. With PWM you still need the controller and flow meter but instead of using a regulating valve to control flow, the PWM controls the speed of the pump.

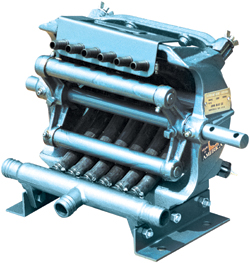

Piston Pumps

Piston pumps are another type of positive displacement pump used in several different industries. As you might have guessed, a piston pump gets its name from the mechanical means used to move the fluid. In this case, a reciprocating piston forces draws liquid in and forces it out of the pump chamber.

There are specific piston pumps designed for the agriculture world. The NGP series piston pump from John Blue is an extremely effective tool for liquid fertilizer application on planters, side dress machines, and other toolbars. They offer a very accurate way to apply fertilizers at a constant rate. These pumps can be driven in several ways, but the most common drive types when used on planters are ground drive and hydraulic drive.

Advantages of Piston Pumps for Fertilizers:

- Priming Capability - these pumps can prime or pull liquid from longer distances when compared to other pump types.

- Extremely accurate despite varying temperatures

- Auto-adjusting for speed changes (maintains application rate)

- Constructed of durable cast iron and stainless components. Properly maintained pumps can last many years.

- Field Serviceable

John Blue Piston Pump Service & Repair Video:

Disadvantages:

- Gritty products can damage pistons

- Lower flow compared to centrifugal pumps

Piston Pump System Requirements

As mentioned earlier, there are two main ways to drive a piston pump: ground drive or hydraulic.

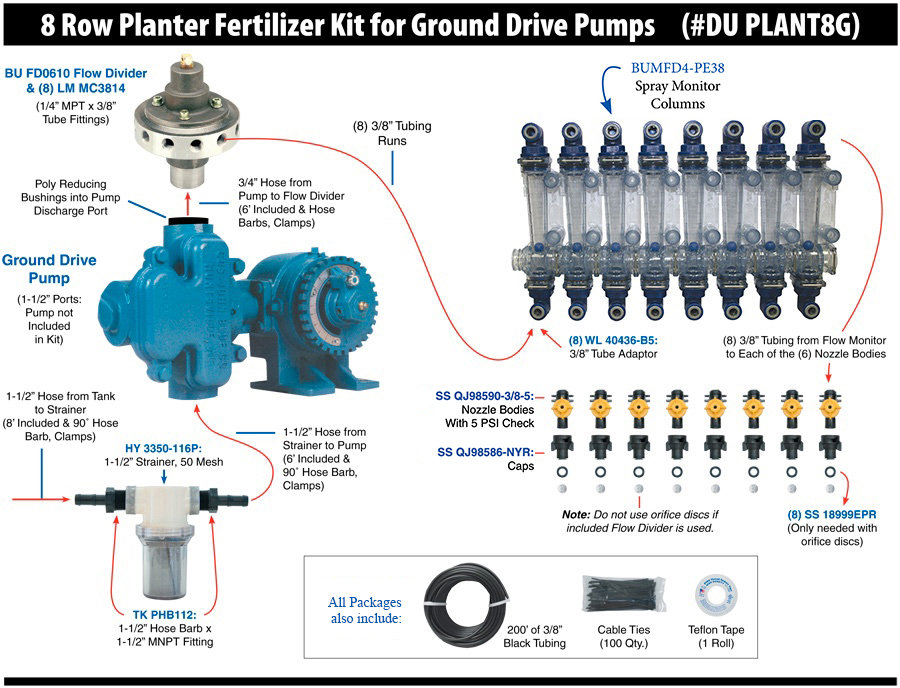

Ground drive either with a dedicated ground drive assembly or planter hex shaft. Ground drive pumps offer extremely accurate performance and do not require all the electronic components like flow meters, regulating valves, or rate controllers.

Ground-driven pumps do require that you calculate the proper pump setting and select sprockets to ensure the crankcase of the pump is rotating at the speed needed to deliver your desired rate. John Blue provides a tool that lets you quickly determine the correct settings with their NGP piston pump setting calculator.

From there you simply need to ensure that you evenly distribute the liquid among each row. This will require a flow divider manifold or orifice discs as well as a set of site gauges to monitor the flow going to each row.

John Blue Ground Drive Piston Pump options:

Ground Drives:

NGP Piston Pumps with Hydraulic Motor

If you prefer, you can drive an NGP piston pump with a hydraulic motor. The motors have a PWM valve that allows you to control your rate by varying the speed of the motor. While this method does not require a regulating valve, you will need a GPS/speed sensor and a flow meter in addition to a rate controller.

Squeeze Pumps

A squeeze pump is unique in that it is designed specifically for planters. They are effective at accurately and evenly distributing fluid over each row. They do not require any additional components such as rate controllers, regulating valves, distributors, etc. Just typical plumbing and sight gauges if desired.

Advantages of Squeeze Pumps

- Simplicity

- Maintains rate when you speed up or slow down

- Pump stops when the planter stops

Disadvantages of Squeeze Pumps

- Not as versatile as other pump types

- Limited pump options available (6 row, 8 row, 12 row, 16 row)

System Requirements for Squeeze Pumps

A fertilizer setup using a squeeze pump is very simple. The pump is ground-driven, so the output is directly related to the speed of the planter. This means you dial in the output you need, and your desired application rate is maintained. There is no need for regulating valves or electronic flow meters.

The pump also serves as the manifold that evenly distributes the liquid over each row. The only additional components you need would be flow monitors so you can watch each row for plugs or low flow.

Conclusion

In conclusion, selecting the best fertilizer pump for your planter system requires careful consideration of several factors, including the type of fertilizer, flow rate needs, precision, and compatibility with your setup. Each pump type-from centrifugal and diaphragm to piston and squeeze pumps-offers unique strengths and trade-offs. Whether you prioritize high volume, precision desired, or simplicity, there's a pump to meet your specific requirements.

At Dultmeier, we understand that no two planter setups are exactly the same, and our team has decades of experience helping customers choose the right pumps for their systems. Whether you need a robust hydraulic-driven pump for high-volume applications or a simple 12-volt diaphragm pump for a smaller planter, we're here to guide you through the selection process. Don't hesitate to reach out for personalized recommendations or browse our selection of pumps and complete fertilizer systems to get started!

Tech Ag & Industrial Sales

Shane Blomendahl is a tech sales veteran at Dultmeier Sales with over 10+ years of experience in liquid handling products covering several industries and applications.