What is Pure H2O?

Crystal clean, pure, and without blemish. If all water entered our appliances, equipment, and food in it's purest form we would have a lot less headaches. Face it - hard water is tough - not just on equipment but on our bodies. If we can introduce pure water into a plumbing system it will accomplish things from reducing friction all the way to keeping maintenance costs lower. Fortunately, we can accomplish this through a process called reverse osmosis.

Think about it this way - let's say you setup two equal plumbing systems but the only factor your change is the water hardness. If you are pumping water that has 450 Parts Per Million (PPM) in System A, versus water that has 10 PPM in System B - which system will outlast the other?

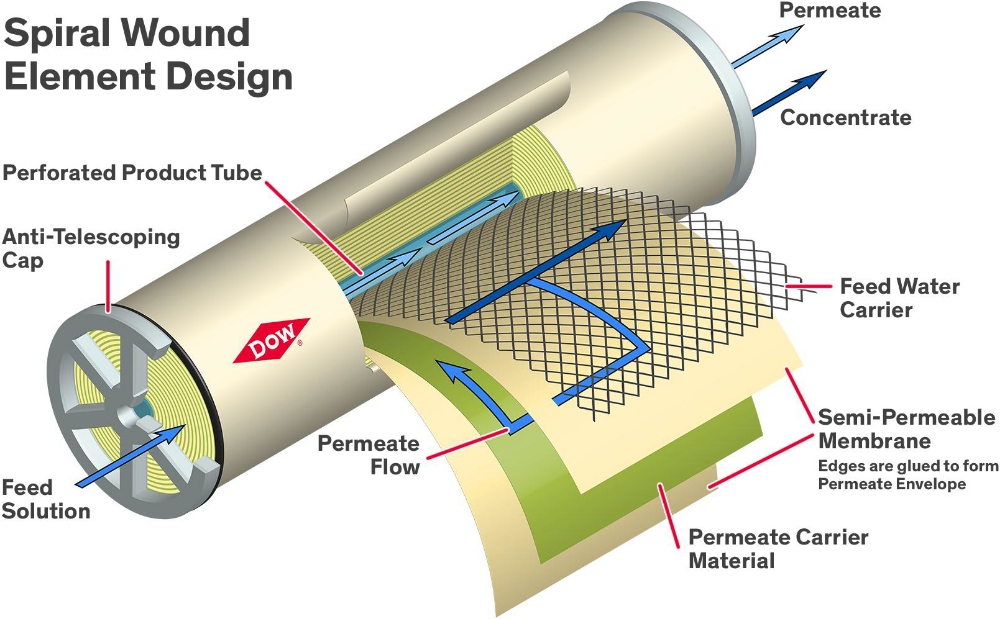

I hope you guessed System B. Common sense tells us the less wear and tear we can put on mechanical pieces of machinery the longer it will last. Therefore, if you have hard water (water that contains more abrasive or suspended particulates) you are going to undoubtedly add to variable expenses in the form of increased operating costs - the upkeep of your equipment will require more routine maintenance and repairs - no way around it. Below you will see a cut-out view of a membrane used in reverse osmosis systems.

But what if I told you a simple investment, up front, could lower those variable costs and effectively keep more money in your pocket? You keep more money in your pocket by allowing your system to run more efficiently and lessen the likelihood of additional maintenance and repairs costs.

Bottom line - if you can keep your system operating longer and minimize down time, whether that's scheduled maintenance or emergency maintenance, more money stays in your pocket.

Determining Water Hardness

Let's get into the heart of this discussion and throw some numbers out there. Water hardness is determined on parts per million. The EPA allows for 500 PPM in drinking water. Vehicle washing requires, a maximum, 50PPM.

More and more greenhouses are beginning to monitor their water hardness, as well. Greenhouses and farmers across the country need to monitor their pH levels constantly. They do this to ensure that their plants are given the correct ratio of nutrients required to improve yields. By rigorously monitoring the purification of the water supply, an operator can ensure that a clear, and controlled, chemical reaction takes place with their soil matter.

The process of reverse osmosis allows operators and farm/greenhouse managers to effectively oversee this chemical reaction - in a much more efficient manner.

Reverse Osmosis & How it Works

Reverse Osmosis is a process in which microscopic particulates are captured by an extremely fine membrane that allows the solute, in this case, water to pass through. This process is so effective that it can take water with 500PPM and reduce that number to less than 10PPM - and, in many instances we can do much better than that.

This process is achieved through pressurization and, as noted above, extremely fine membranes or filters. The solute is retained on the pressurized side of the membrane and the solvent is allowed to pass through the membrane. The reason this process must occur under pressure is that the solution needs to be forced through the fine holes of the membrane. In many systems there will be multiple stages of filtration.

The first filtration step will occur through an extremely crude manner. In many instances, the process will include a sand bed filtration that is gravity fed. This step is no more complicated than allowing the solution to percolate through a large sand bed - thus extracting many of the large particles that would clog finer filters and membranes - which are downstream in the plumbing system.

The next stage typically involves another filter, or series of filters, that catch particulates and suspended particles that were small enough to pass through the sand bed -which is stage 1 of the filtration process. By implementing this second stage filter the process, in most instances, the solution is ready to actually pass through the finer filters/membranes - thus completing the reverse osmosis process.

Prior to running the solution through the final filtration stages, it must be ran through a "booster pump" that creates the pressurized portion of the system.

Once under pressure, the solution is ran through another membrane or series of membranes. Depending on the water hardness, it might be necessary to use a series of reverse osmosis membranes to reach the desired PPM the operation requires. Basic system components for a reverse osmosis system, used in the vehicle washing industry, can be viewed here.

Upstart University Video Explanation

Here is a video from Upstart University on how reverse osmosis can benefit farmers and greenhouse managers.

For further product questions or inquiries about reverse osmosis systems and or replacement components and parts - don't hesitate to contact us or check out our website at Dultmeier.com - Thanks for stopping by and take care!